Nissan Juke Service and Repair Manual : Water outlet

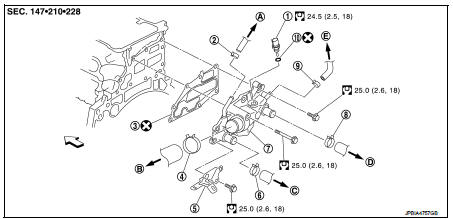

Exploded View

1. Engine coolant temperature sensor

2. Clamp

3. Gasket

4. Clamp

5. Bracket

6. Clamp

7. Water outlet

8. Clamp

9. Clamp

10. Washer

A. To electric throttle control actuator

B. To radiator

C. To CVT oil warmer

D. To heater core

E. To electric throttle control actuator

: Engine front

: Engine front

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Drain engine coolant from radiator. Refer to CO-37, "Draining".

CAUTION:

• Perform this step when engine is cold.

2. Remove air duct (inlet) and air ducts. Refer to EM-161, "Removal and Installation".

3. Disconnect radiator hose (upper). Refer to CO-42, "Exploded View".

4. Disconnect harness connector from engine coolant temperature sensor.

5. Remove water hoses and heater hoses.

6. Remove water outlet.

7. Remove engine coolant temperature sensor from water outlet, if necessary.

INSTALLATION

Installation is the reverse order of removal.

Inspection

INSPECTION AFTER REMOVAL

Water Control Valve

• Place a thread (A) so that it is caught in the valves of water control valve (1). Immerse fully in a container (B) filled with water. Heat while stirring.

• The valve opening temperature is the temperature at which the valve opens and falls from the thread.

• Continue heating. Check the continuous valve lifting toward maximum valve lift.

NOTE

:

The maximum valve lift amount standard temperature for water

control valve is the reference value.

• After checking the maximum valve lift amount, lower the water temperature and check the valve closing temperature.

Standard: Refer to CO-54, "Water Control Valve".

• If out of the standard, replace water control valve.

INSPECTION AFTER INSTALLATION

• Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the radiator cap tester (commercial service tool). Refer to CO-37, "Inspection".

• Start and warm up the engine. Check visually that there is no leakage of engine coolant.

Thermostat

Thermostat

Exploded View

1. Radiator hose (upper)

2. Water inlet

3. Rubber ring

4. Thermostat

A. To radiator

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

Removal and Installation

...

Other materials:

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...

How to set SRT code

Description

OUTLINE

In order to set all SRTs, the self-diagnoses as in the “SRT ITEM” table must

have been performed at least

once. Each diagnosis may require actual driving for a long period of time under

various conditions.

SRT ITEM

The table below shows required self-diagnostic items t ...

Ambient sensor

Removal and Installation

REMOVAL

1. Remove bumper fascia assembly. Refer to EXT-13, "Removal and

Installation".

2. Disengage fixing pawl, and then remove ambient sensor (1)

from air guide RH.

: Pawl

3. Disconnect ambient sensor connector (2), and then remove

ambient sensor.

INS ...