Nissan Juke Service and Repair Manual : System

Relay control system

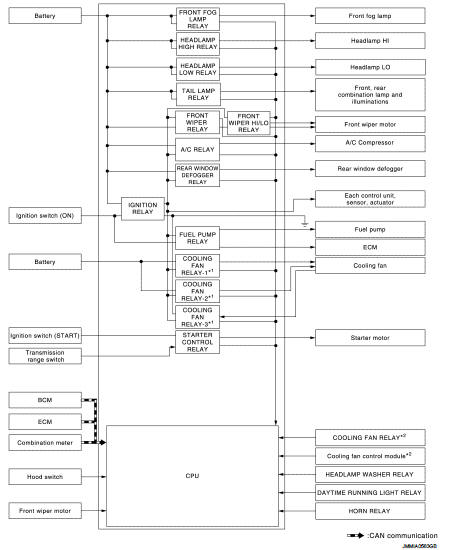

RELAY CONTROL SYSTEM : System Diagram

*1: Except for MR16DDT engine models *2: For MR16DDT engine models

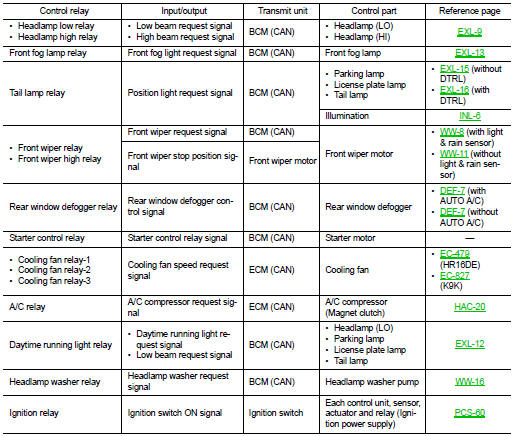

RELAY CONTROL SYSTEM : System Description

IPDM E/R activates the internal control circuit to perform the relay ON-OFF control according to the input signals from various sensors and the request signals received from control units via CAN communication.

CAUTION:

IPDM E/R integrated relays cannot be removed.

RELAY CONTROL SYSTEM : Fail-Safe

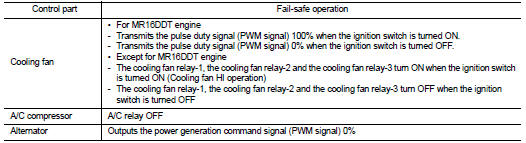

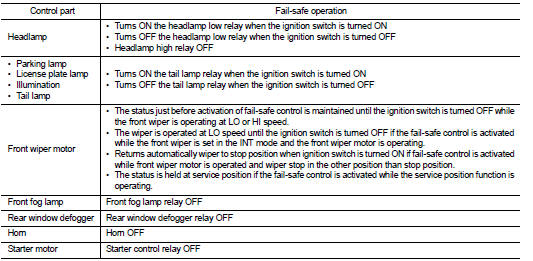

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible, IPDM E/R performs fail-safe control. After CAN communication recovers normally, it also returns to normal control.

If No CAN Communication Is Available With ECM

If No CAN Communication Is Available With BCM

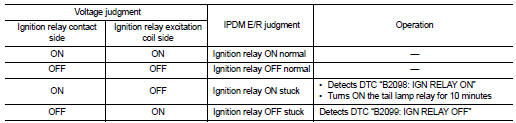

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

• IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay inside it.

• IPDM E/R judges the ignition relay error if the voltage differs between the contact circuit and the excitation coil circuit.

• If the ignition relay cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to alert the user to the ignition relay malfunction when the ignition switch is turned OFF.

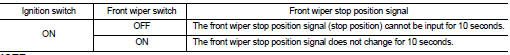

FRONT WIPER PROTECTION FUNCTION

IPDM E/R detects front wiper stop position by a front wiper stop position signal.

When a front wiper stop position signal is in the conditions listed below, IPDM E/R stops power supply to wiper after repeating a front wiper 10 seconds activation and 20 seconds stop.

NOTE

:

This operation status can be confirmed on the IPDM E/R “Data Monitor” that

displays “BLOCK” for the item

“WIP PROT” while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter control relay to protect the starter motor when the starter control relay remains active for 90 seconds.

Power control system

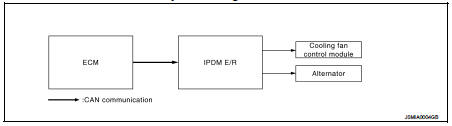

POWER CONTROL SYSTEM : System Diagram

POWER CONTROL SYSTEM : System Description

COOLING FAN CONTROL (ONLY FOR MODELS WITH MR16DDT ENGINE)

IPDM E/R outputs pulse duty signal (PWM signal) to the cooling fan control module according to the status of the cooling fan speed request signal received from ECM via CAN communication. Refer to EC-61, "COOLING FAN CONTROL : System Diagram".

NOTE

:

After ignition switch OFF, IPDM E/R turn the cooling fan relay ON and outputs

pulse duty signal (PWM signal)

to the cooling fan control module according to the request signal from ECM for

cooling the engine according to

the situation.

ALTERNATOR CONTROL

IPDM E/R outputs power generation command signal (PWM signal) to the alternator according to the status of the power generation command value signal received from ECM via CAN communication. Refer to CHG-9, "POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM : System Diagram (Gasoline Engine Models)".

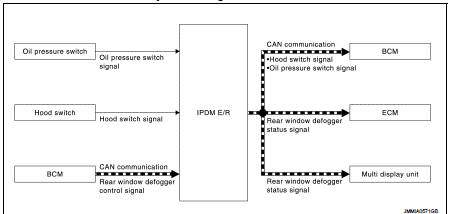

Signal buffer system

SIGNAL BUFFER SYSTEM : System Diagram

SIGNAL BUFFER SYSTEM : System Description

• NOTE

:

Only for K9K engine models

IPDM E/R reads the status of the oil pressure switch and transmits the oil

pressure switch signal to BCM via

CAN communication. Refer to MWI-12, "OIL PRESSURE WARNING LAMP : System

Diagram".

• IPDM E/R reads the status of the hood switch and transmits the hood switch signal to BCM via CAN communication.

Refer to SEC-174, "VEHICLE SECURITY SYSTEM : System Diagram".

• IPDM E/R receives the rear window defogger control signal from BCM via CAN communication and transmits the rear window defogger status signal to ECM and multi display unit via CAN communication. Refer to DEF-7, "WITH AUTO A/C : System Diagram" (with AUTO A/C) or DEF-7, "WITHOUT AUTO A/C : System Diagram" (without AUTO A/C).

Power consumption control system

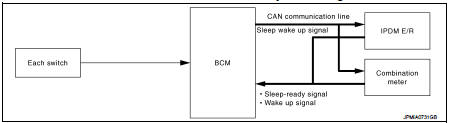

POWER CONSUMPTION CONTROL SYSTEM : System Diagram

POWER CONSUMPTION CONTROL SYSTEM : System Description

OUTLINE

• IPDM E/R incorporates a power consumption control function that reduces the power consumption according to the vehicle status.

• IPDM E/R changes its status (control mode) with the sleep wake up signal received from BCM via CAN communication.

Normal mode (wake-up)

- CAN communication is normally performed with other control units.

- Individual unit control by IPDM E/R is normally performed.

Low power consumption mode (sleep) - Low power consumption control is active.

- CAN transmission is stopped.

SLEEP MODE ACTIVATION

• IPDM E/R judges that the sleep-ready conditions are fulfilled when the ignition switch is OFF and none of the conditions below are present. Then it transmits a sleep-ready signal (ready) to BCM via CAN communication.

- Outputting signals to actuators - Switches or relays operating - Output requests are being received from control units via CAN communication.

• IPDM E/R stops CAN communication and enters the low power consumption mode when it receives a sleep wake up signal (sleep) from BCM and the sleep-ready conditions are fulfilled.

WAKE-UP OPERATION

• IPDM E/R changes from the low power consumption mode to the normal mode when

it receives a sleep

wake-up signal (wake up) from BCM or any of the following conditions is

fulfilled. In addition, it transmits a

sleep-ready signal (not-ready) to BCM via CAN communication to report the CAN

communication start.

- Ignition switch ON

- An output request is received from a control unit via CAN communication.

Component parts

Component parts

Component Parts Location

1. IPDM E/R

A. Engine room (LH) ...

Diagnosis system (IPDM E/R)

Diagnosis system (IPDM E/R)

Diagnosis Description

AUTO ACTIVE TEST

Description

In auto active test mode, the IPDM E/R sends a drive signal to the following

systems to check their operation.

• Oil pressure warning lamp (o ...

Other materials:

U1000 can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real-time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent malfunction

detection ability.

Many electronic control units are equipped onto a vehicle, and ...

P0840 transmission fluid pressure SEN/SW A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignition switch

OFF and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the mal ...

Compressor dose dot operate

Description

SYMPTOM

Compressor dose not operate.

Diagnosis Procedure

NOTE:

• Perform self-diagnosis with CONSULT-III before performing symptom diagnosis.

If any malfunction result or

DTC is detected, perform the corresponding diagnosis.

• Check that refrigerant is enclosed in cooler cycle n ...