Nissan Juke Service and Repair Manual : Structure and operation

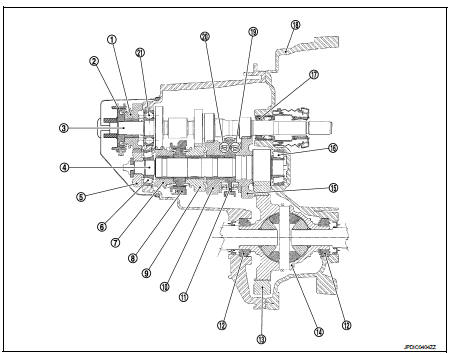

Sectional View

1. 5th input gear

2. 5th-reverse synchronizer hub assembly

3. Input shaft

4. Mainshaft

5. 5th main gear

6. Mainshaft rear bearing

7. 4th main gear

8. 3rd-4th synchronizer hub assembly

9. 3rd main gear

10. 2nd main gear

11. 1st-2nd synchronizer hub assembly

12. Differential side bearing

13. Final gear

14. Differential

15. 1st main gear

16. Mainshaft front bearing

17. Input shaft front bearing

18. Clutch housing

19. 1st double-cone synchronizer

20. 2nd double-cone synchronizer

21. Input shaft rear bearing

System Description

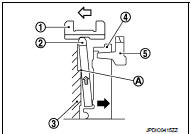

DOUBLE-CONE SYNCHRONIZER

Double-cone synchronizers are adopted for 1st and 2nd gears to reduce operating force of the shifter lever

1 : Outer baulk ring

2 : 2nd main gear

3 : Synchronizer cone

4 : Inner baulk ring

5 : 1st main gear

6 : 1st-2nd coupling sleeve

REVERSE GEAR NOISE PREVENTION FUNCTION (REVERSE BRAKE)

Description

Soon after the clutch is disengaged, the input shaft is still rotating due to

inertia. This may cause a gear noise

when the gear is shifted to reverse position. The reverse gear noise prevention

function stops the rotation of

the input shaft and enables smooth gear shifting when the reverse gear is

selected.

Operation Principle

1. When the gear is shifted to reverse position, 5th-reverse coupling

sleeve (1) slides in the reverse direction. (

)

5 : 5th input gear

2. Synchronizer levers (2) with support point (A) at 5th-reverse

synchronizer hub (3) presses 5th-reverse baulk ring (4). (

)

3. Friction that is generated at 5-reverse baulk ring presses synchronizer

lever on 5th-reverse coupling sleeve. (

)

4. 5th-reverse coupling sleeve that is pressed by synchronizer

lever stops the rotation of input shaft.

Component parts

Component parts

Component Parts Location

POSITION SWITCH

1 : Position switch

...

DTC/Circuit diagnosis

DTC/Circuit diagnosis

POSITION SWITCH

BACK-UP LAMP SWITCH : Component Inspection

1.CHECK BACK-UP LAMP SWITCH

1. Disconnect position switch connector. Refer to TM-24, "Removal and

Installation".

2. Check con ...

Other materials:

Aluminum alloy wheels

Wash regularly with a sponge dampened in a mild soap solution, especially during

winter months in areas where road salt is used. Salt could discolor the wheels if

not removed.

CAUTION

Follow the directions below to avoid staining or discoloring the wheels:

• Do not use a cleaner that uses str ...

Wiring diagram

Engine control system

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...