Nissan Juke Service and Repair Manual : Steering switch ground circuit

Description

Transmits the steering switch signal to NAVI control unit.

Diagnosis Procedure

1.CHECK STEERING SWITCH SIGNAL GROUND CIRCUIT

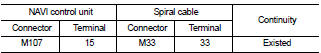

1. Disconnect NAVI control unit connector and spiral cable connector.

2. Check continuity between NAVI control unit harness connector and spiral cable harness connector.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair harness or connector. 2.CHECK SPIRAL CABLE

Check spiral cable.

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace spiral cable. Refer to SR-16, "Exploded View".

3.CHECK GROUND CIRCUIT

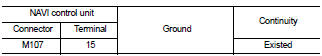

1. Connect NAVI control unit connector.

2. Check continuity between NAVI control unit harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Replace NAVI control unit. Refer to AV-84, "Removal and Installation".

4.CHECK STEERING SWITCH

1. Turn ignition switch OFF.

2. Check steering switch. Refer to AV-75, "Component Inspection".

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace steering switch. Refer to AV-91, "Exploded View".

Component Inspection

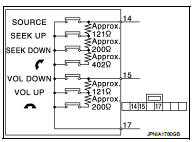

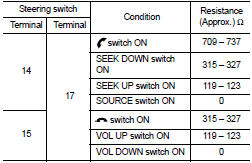

Measure the resistance between the steering switch connector.

Standard

Steering switch signal B circuit

Steering switch signal B circuit

Description

Transmits the steering switch signal to NAVI control unit.

Diagnosis Procedure

1.CHECK STEERING SWITCH SIGNAL B CIRCUIT

1. Disconnect NAVI control unit connector and spiral cable conne ...

Other materials:

Radiator core support

HR16DE

HR16DE : Exploded View

1. Radiator core support upper

2. Air guide RH (MT models)

3. Radiator core support lower

4. Air guide LH 5. Air guide (upper)

6. Air guide LH (CVT models)

7. Air guide RH (CVT models)

: N·m (kg-m, ft-lb)

HR16DE : Removal and Installation

RADIATOR CORE SU ...

Front wheel hub and knuckle

Exploded View

1. Steering knuckle

2. Splash guard

3. Hub bolt

4. Wheel hub assembly (Bearing-integrated

type)

5. Disc rotor

6. Wheel hub lock nut

7. Adjusting cap

8. Cotter pin

A. Tightening must be done following the installation procedure. Refer to

FAX-11, "Removal and Insta ...

CVT fluid

Inspection

CHECKING CVT FLUID

The fluid level should be checked with the fluid warmed up to 50 to 80°C (122

to 176°F). The fluid level check

procedure is as follows:

1. Check for fluid leakage.

2. With the engine warmed up, drive the vehicle in an urban area.

When ambient temperature is 20 ...