Nissan Juke Service and Repair Manual : Reservoir tank cap

Inspection

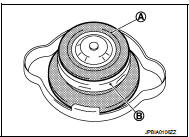

• Check valve seat of reservoir tank cap.

- Check if valve seat (A) is swollen to the extent that the edge of the metal plunger (B) cannot be seen when watching it vertically from the top.

- Check if valve seat has no soil and damage.

• Pull negative-pressure valve to open it, and check that it close completely when released.

- Check that there is no dirt or damage on the valve seat of reservoir tank cap negative-pressure valve.

- Check that there are no unusualness in the opening and closing conditions of negative-pressure valve.

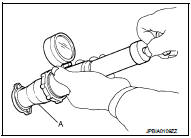

• Check reservoir tank cap relief pressure.

- When connecting reservoir tank cap to the radiator cap tester (commercial service tool) and the radiator cap tester adapter (commercial service tool) (A), apply engine coolant to the cap seal surface.

Standard and limit : Refer to CO-76, "Radiator".

• Replace reservoir tank cap if there is an unusualness related to the above three.

CAUTION:

When installing reservoir tank cap, thoroughly wipe out the reservoir tank

filler neck to remove any

waxy residue or foreign material.

Engine coolant

Engine coolant

Inspection

LEVEL

• Check that the reservoir tank engine coolant level is within the

“MIN” to “MAX” when the engine is cool.

A : MAX

B : MIN

• Adjust the engine coolant level if necessary.

LEA ...

Other materials:

Avoiding collision and rollover

WARNING

Failure to operate this vehicle in a safe and prudent manner may result in

loss of control or an accident.

Be alert and drive defensively at all times. Obey all traffic regulations. Avoid

excessive speed, high speed cornering, or sudden steering maneuvers, because these

driving pract ...

Precaution for Brake Control system

• Always perform a pre-driving check to drive the vehicle.• Always perform a

pre-driving check to drive the vehicle.

• Always check speed and safety while driving the vehicle.

• Always check speed and safety while driving the vehicle.

• To operate CONSULT-III while driving, more than one pers ...

Front seat-mounted side-impact supplemental air bag and roof-mounted curtain

side-impact supplemental air bag systems

The side air bags are located in the outside of the seatback of the front seats.

The curtain air bags are located in the side roof rails. All of the information,

cautions and warnings in this manual still apply and must be followed.

The side air bags and curtain air bags are designed to infla ...