Nissan Juke Service and Repair Manual : Refilling

1. Install reservoir tank if removed and radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

Radiator drain plug : Refer to CO-42, "Exploded View".

• If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-228, "Disassembly and Assembly".

2. Check that each hose clamp has been firmly tightened.

3. Remove air duct (between air cleaner case and electric throttle control actuator). Refer to EM-161, "Exploded View".

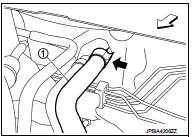

4. Disconnect heater hose (1) at position (

) in the figure.

: Vehicle front

: Vehicle front

• Enhance heater hose as high as possible.

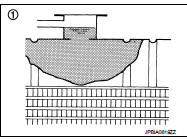

5. Fill radiator (1) to specified level.

CAUTION:

Never adhere the engine coolant to electronic equipments

(alternator etc.).

• Pour coolant slowly of less than 2 (2-1/8 US qt, 1-3/4 Imp qt) a minute to allow air in system to escape.

• When engine coolant overflows disconnected heater hose, connect heater hose, and continue filling the engine coolant.

• Use Genuine NISSAN Engine Coolant or equivalent in its quality mixed with water (distilled or demineralized). Refer to MA-13, "Fluids and Lubricants".

Engine coolant capacity (With reservoir tank at “MAX” level) Refer to CO-54, "Periodical Maintenance Specification".

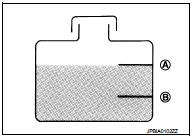

6. Refill reservoir tank to “MAX” level line with engine coolant.

A : MAX

B : MIN

Reservoir tank engine coolant capacity

(At “MAX” level)

Refer to CO-54, "Periodical Maintenance Specification".

7. Install air duct (between air cleaner case and electric throttle control actuator). Refer to EM-161, "Exploded View".

8. Install radiator cap.

9. Warm up engine until opening thermostat. Standard for warming-up time is approximately 10 minutes at 3,000 rpm.

• Check thermostat opening condition by touching radiator hose (lower) to see a flow of warm water.

CAUTION:

Watch water temperature gauge so as not to overheat engine

.

10. Stop the engine and cool down to less than approximately 50°C (122°F).

• Cool down using fan to reduce the time.

• If necessary, refill radiator up to filler neck with engine coolant.

CAUTION:

Never adhere the engine coolant to electronic equipments (alternator etc.).

11. Refill reservoir tank to “MAX” level line with engine coolant.

12. Repeat steps 5 through 10 two or more times with radiator cap installed until engine coolant level no longer drops.

13. Check cooling system for leakage with engine running.

14. Warm up the engine, and check for sound of engine coolant flow while running engine from idle up to 3,000 rpm with heater temperature controller set at several position between “COOL” and “WARM”.

• Sound may be noticeable at heater unit.

15. Repeat step 14 three times.

16. If sound is heard, bleed air from cooling system by repeating step 5 through 10 until reservoir tank level no longer drops.

Draining

Draining

WARNING:

• Never remove radiator cap when engine is hot. Serious burns may occur from

high-pressure engine

coolant escaping from radiator.

• Wrap a thick cloth around the radiator cap. Slowly tur ...

Flushing

Flushing

1. Install reservoir tank if removed and radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

Radiator drain plug : Refer to CO-42, "Exploded View".

• ...

Other materials:

Service Notice or Precautions for Manual Transaxle

CAUTION:

• Never reuse CSC (Concentric Slave Cylinder). Because CSC slides back to the

original position

every time when removing transaxle assembly. At this timing, dust on the sliding

parts may damage

a seal of CSC and may cause clutch fluid leakage. Refer to CL-27, "Removal and

Inst ...

P0500 VSS

Description

The vehicle speed signal is sent to the combination meter from the “ABS

actuator and electric unit (control

unit)” by CAN communication line. The combination meter then sends a signal to

the ECM by CAN communication

line.

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC P0500 is d ...

Door motor

Exploded View

LEFT SIDE

1. A/C unit assembly

2. Intake door lever

3. Intake door motor

4. Air mix door motor

5. Upper air mix door rod

6. Upper air mix door lever

7. Lower air mix door lever

8. Lower air mix door rod

RIGHT SIDE

1. A/C unit assembly

2. Main link

3. Sub defrost ...