Nissan Juke Service and Repair Manual : Radiator cap : Inspection

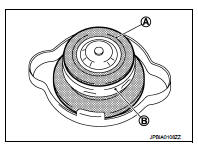

Check valve seat (A) of radiator cap.

B : Metal plunger

- Check that valve seat is swollen to the extent that the edge of the plunger cannot be seen when watching it vertically from the top.

- Check that valve seat has no soil and damage.

Pull negative-pressure valve to open it, and that it close completely when released.

- Check that there is no dirt or damage on the valve seat of radiator cap negative-pressure valve.

- Check that there are no unusualness in the opening and closing conditions of negative-pressure valve.

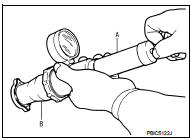

• Check radiator cap relief pressure.

Standard and Limit : Refer to CO-54, "Radiator".

- When connecting radiator cap to the radiator cap tester (commercial service tool) (A) and the radiator cap tester adapter (commercial service tool) (B), apply engine coolant to the cap seal surface.

• Replace radiator cap if there is an unusualness related to the above three.

CAUTION:

When installing radiator cap, thoroughly wipe out the radiator filler neck to

remove any waxy residue

or foreign material.

Radiator

Radiator

...

Radiator : Inspection

Radiator : Inspection

Check radiator for mud or clogging. If necessary, clean radiator as follows.

CAUTION:

• Be careful not to bend or damage radiator fins.

• When radiator is cleaned without removal, remove all surr ...

Other materials:

U0140 lost communication (BCM)

Description

CAN (Controller Area Network) is a serial communication line for real-time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent malfunction

detection ability.

Many electronic control units are equipped onto a vehicle, and ...

P1740 select solenoid

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignition switch

OFF and wait at least 10 seconds before performing the next test.

After the repair, p ...

Antenna

To remove the antenna, hold the bottom of the antenna and turn it counterclockwise.

To install the antenna, turn the antenna clockwise and tighten.

CAUTION

• To avoid damaging or deforming the antenna, be sure to fold down (if so

equipped) or remove the antenna under the following conditions. ...