Nissan Juke Service and Repair Manual : Primary speed sensor

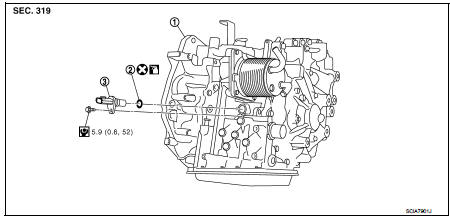

Exploded View

1. Transaxle assembly

2. O-ring

3. Primary speed sensor

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Genuine NISSAN CVT Fluid NS-2

: Genuine NISSAN CVT Fluid NS-2

Removal and Installation

REMOVAL

1. Remove the battery. Refer to PG-124, "Removal and Installation".

2. Remove ECM bracket. Refer to EC-447, "Removal and Installation".

3. Remove primary speed sensor connector.

4. Remove primary speed sensor.

5. Remove O-ring from primary speed sensor.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

• Never reuse O-ring.

• Apply CVT fluid to O-ring.

Inspection and Adjustment

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage. Refer to TM-480, "Inspection".

ADJUSTMENT AFTER INSTALLATION

Adjust the CVT fluid level. Refer to TM-379, "Adjustment".

Control valve

Control valve

Exploded View

COMPONENT PARTS LOCATION

1. Transaxle assembly

2. Control valve

3. Bracket

4. O-ring

5. Oil strainer assembly

6. Magnet

7. Drain plug gasket

8. Drain plug

9. Oil pan mo ...

Secondary speed sensor

Secondary speed sensor

Exploded View

1. Transaxle assembly

2. Secondary speed sensor

3. O-ring

: Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: Genuine NISSAN CVT Fluid NS-2

Removal and Installat ...

Other materials:

Mixture ratio self-learning value

clear

Description

This describes how to erase the mixture ratio self-learning value. For the

actual procedure, follow the instructions

in “Diagnosis Procedure”.

Work Procedure

With CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Select “SELF-LEARNING CONT” in “WORK S ...

Intelligent key battery

Removal and Installation

1. Release the lock knob at the back of the Intelligent Key and remove the

mechanical key.

2. Insert a flat-blade screwdriver (A) wrapped with a cloth into the

slit of the corner and twist it to separate the upper part from the

lower part.

CAUTION:

• Do not touch t ...

P1611 ID discord, IMMU-ECM

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check DTC in “Self Diagnostic Result” mode of “ENGINE” using CONSULT-III.

Is DTC detected?

YES >> Go to SEC-53, "Diagnosis Procedure".

NO >> ...