Nissan Juke Service and Repair Manual : Precaution for Liquid Gasket

REMOVAL OF LIQUID GASKET

• After removing the mounting bolts and nuts, separate the mating surface using a seal cutter and remove the liquid gasket.

CAUTION:

Be careful not to damage the mating surfaces.

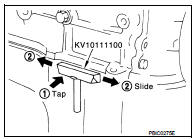

• In areas where the cutter is difficult to use, use a plastic hammer to lightly tap the gasket applied area.

CAUTION:

If for some unavoidable reason a tool such as a flat-bladed

screwdriver is used, be careful not to damage the mating surfaces

.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove the old liquid gasket adhering to the gasket application surface and the mating surface.

• Remove the liquid gasket completely from the groove of the gasket application surface, mounting bolts and bolt holes.

2. Wipe the gasket application surface and the mating surface with white gasoline (lighting and heating use) to remove adhering moisture, grease and foreign materials.

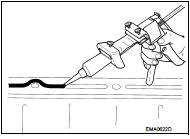

3. Attach the liquid gasket to the tube presser.

Use Genuine Liquid Gasket or equivalent.

4. Apply the gasket without breaks to the specified location with the specified dimensions.

• If there is a groove for the liquid gasket application, apply the gasket to the groove.

• As for the bolt holes, normally apply the gasket inside the holes. If specified, it should be applied outside the holes. Make sure to read the instruction in this manual.

• Within five minutes of gasket application, install the mating component.

• If the liquid gasket protrudes, wipe it off immediately.

• Do not retighten after the installation.

• After 30 minutes or more have passed from the installation, fill the engine oil and coolant.

CAUTION:

If there are instructions in this manual, observe them.

Precaution Necessary for Steering Wheel Rotation

after Battery Disconnect

Precaution Necessary for Steering Wheel Rotation

after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all contro ...

Preparation

Preparation

Special Service Tool

...

Other materials:

Diagnosis system (BCM) (without intelligent key system)

Common item

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver a ...

Push-button ignition switch positions

LOCK (Normal parking position)

The ignition switch can only be locked in this position.

The ignition switch will be unlocked when it is pushed to the ACC position while

carrying the Intelligent Key.

ACC (Accessories)

This position activates electrical accessories such as the radio, when the en ...