Nissan Juke Service and Repair Manual : Power window motor

DRIVER SIDE

DRIVER SIDE : Component Function Check

1. CHECK FRONT POWER WINDOW MOTOR (DRIVER SIDE) OPERATION

Check front power window motor (driver side) operation with power window main switch.

Is the inspection result normal? YES >> INSPECTION END

NO >> Refer to PWC-26, "DRIVER SIDE : Diagnosis Procedure".

DRIVER SIDE : Diagnosis Procedure

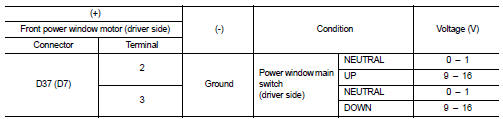

1.CHECK FRONT POWER WINDOW MOTOR (DRIVER SIDE) INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front power window motor (driver side) connector.

3. Turn ignition switch ON.

4. Check voltage between front power window motor (driver side) harness connector and ground.

(): RHD models Is the inspection result normal? YES >> Replace front power window motor (driver side).

NO >> GO TO 2.

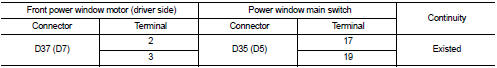

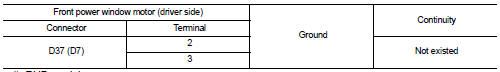

2.CHECK FRONT POWER WINDOW MOTOR (DRIVER SIDE) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect power window main switch connector.

3. Check continuity between front power window motor (driver side) harness connector and power window main switch harness connector.

4. Check continuity between front power window motor (driver side) harness connector and ground.

(): RHD models

Is the inspection result normal? YES >> Replace power window main switch.

NO >> Repair or replace harness.

Passenger side

PASSENGER SIDE : Component Function Check

1. CHECK FRONT POWER WINDOW MOTOR (PASSENGER SIDE) OPERATION

Check front power window motor (passenger side) operation with power window main switch or front power window switch (passenger side).

Is the inspection result normal? YES >> INSPECTION END

NO >> Refer to PWC-27, "PASSENGER SIDE : Diagnosis Procedure".

PASSENGER SIDE : Diagnosis Procedure

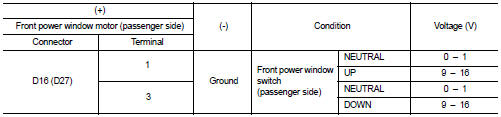

1.CHECK FRONT POWER WINDOW MOTOR (PASSENGER SIDE) INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front power window motor (passenger side) connector.

3. Turn ignition switch ON.

4. Check voltage between front power window motor (passenger side) harness connector and ground.

(): RHD models

Is the inspection result normal? YES >> Replace front power window motor (passenger side).

NO >> GO TO 2.

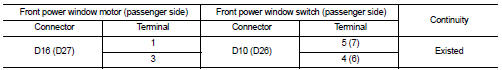

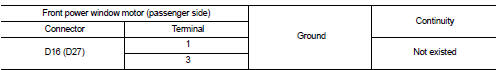

2.CHECK FRONT POWER WINDOW MOTOR (PASSENGER SIDE) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front power window switch (passenger side) connector.

3. Check continuity between front power window motor (passenger side) harness connector and front power window switch (passenger side) harness connector.

4. Check continuity between front power window motor (passenger side) harness connector and ground.

(): RHD models

Is the inspection result normal? YES >> Replace front power window switch (passenger side).

NO >> Repair or replace harness.

Rear LH

REAR LH : Component Function Check

1.CHECK REAR POWER WINDOW MOTOR LH OPERATION

Check rear power window motor LH operation with power window main switch or rear power window switch LH.

Is the inspection result normal? YES >> INSPECTION END

NO >> Refer to PWC-28, "REAR LH : Diagnosis Procedure".

REAR LH : Diagnosis Procedure

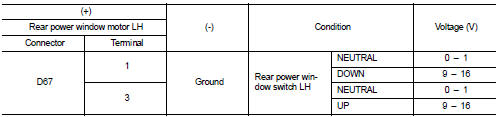

1.CHECK REAR POWER WINDOW MOTOR LH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect rear power window motor LH connector.

3. Turn ignition switch ON.

4. Check voltage between rear power window motor LH harness connector and ground.

Is the inspection result normal? YES >> Replace rear power window motor LH.

NO >> GO TO 2.

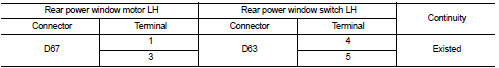

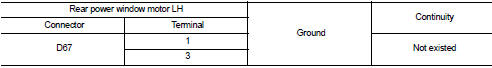

2.CHECK REAR POWER WINDOW MOTOR LH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear power window switch LH connector.

3. Check continuity between rear power window motor LH harness connector and rear power window switch LH harness connector.

4. Check continuity between rear power window motor LH connector and ground.

Is the inspection result normal? YES >> Replace rear power window switch LH.

NO >> Repair or replace harness.

Rear RH

REAR RH : Component Function Check

1. CHECK REAR POWER WINDOW MOTOR RH OPERATION

Check rear power window motor RH operation with power window main switch or rear power window switch RH.

Is the inspection result normal? YES >> INSPECTION END

NO >> Refer to PWC-29, "REAR RH : Diagnosis Procedure".

REAR RH : Diagnosis Procedure

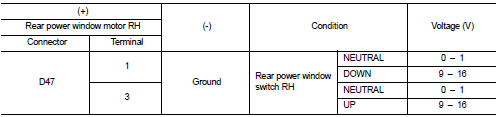

1.CHECK REAR POWER WINDOW MOTOR RH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect rear power window motor RH connector.

3. Turn ignition switch ON.

4. Check voltage between rear power window motor RH harness connector and ground.

Is the inspection result normal? YES >> Replace rear power window motor RH.

NO >> GO TO 2.

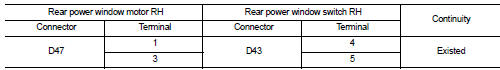

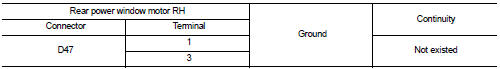

2.CHECK REAR POWER WINDOW MOTOR RH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear power window switch RH connector.

3. Check continuity between rear power window motor RH harness connector and rear power window switch RH harness connector.

4. Check continuity between rear power window motor RH harness connector and ground.

Is the inspection result normal? YES >> Replace rear power window switch RH.

NO >> Repair or replace harness.

Rear power window switch

Rear power window switch

Component Function Check

1. CHECK REAR POWER WINDOW SWITCH FUNCTION

Check rear power window motor operation with rear power window switch.

Is the inspection result normal?

YES >> INSPECTIO ...

Encoder circuit

Encoder circuit

Component Function Check

1.CHECK ENCODER OPERATION

Check that front driver side door glass perform AUTO UP/DOWN operation

normally when power window

main switch is operated.

Is the inspection ...

Other materials:

Meters and gauges

1. Tachometer

2. Engine coolant temperature gauge

3. Vehicle information display

— Odometer/twin trip odometer

— Trip computer

— Torque vectoring AWD (AWD model)

— Outside air temperature

4. Fuel gauge

5. Speedometer

6. Warning/indicator lights

7. Instrument brightness control ...

Air conditioning system refrigerant and lubricant recommendations

The air conditioning system in your NISSAN vehicle must be charged with the

refrigerant HFC-134a (R-134a) and the oil, NISSAN A/C system oil Type R or the exact

equivalents.

CAUTION

The use of any other refrigerant or oil will cause severe damage to the air

conditioning system and will requi ...

Off position warning does not operate

Diagnosis Procedure

1.CHECK DTC WITH BCM AND COMBINATION METER

Check that DTC is not detected with BCM and combination meter.

Is the inspection result normal?

YES >> GO TO 2.

NO-1 >> Refer to BCS-67, "DTC Index". (BCM)

NO-2 >> Refer to MWI-36, "DTC Index&qu ...