Nissan Juke Service and Repair Manual : Periodic maintenance

Periodic Maintenance

The following tables show the normal maintenance schedule. Depending upon weather and atmospheric conditions, varying road surfaces, individual driving habits and vehicle usage, additional or more frequent maintenance may be required.

Periodic maintenance beyond the last period shown on the tables requires similar maintenance.

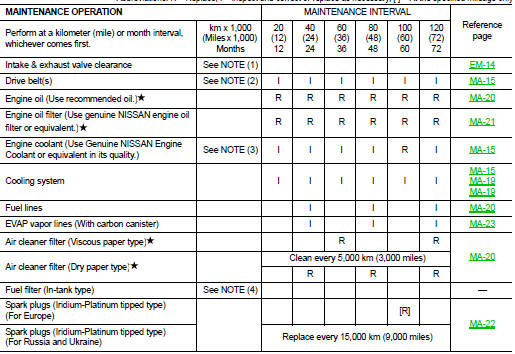

ENGINE AND EMISSION CONTROL MAINTENANCE (MR16DDT PETROL ENGINE)

Abbreviations: R = Replace, I = Inspect and correct or replace as necessary, [ ] = At the specified mileage only

NOTE

:

• Maintenance items with “ ” should be performed more frequently according to

“Maintenance under severe driving conditions”.

• (1) Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

• (2) Replace the drive belt if found damaged.

• (3) Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to avoid possible aluminum corrosion within the engine cooling system caused by the use of non-genuine engine coolant. First replace at 100,000 km (60,000 miles)/60 months, then every 60,000 km (36,000 miles)/48 months. Perform “I” (Checking the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

• (4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

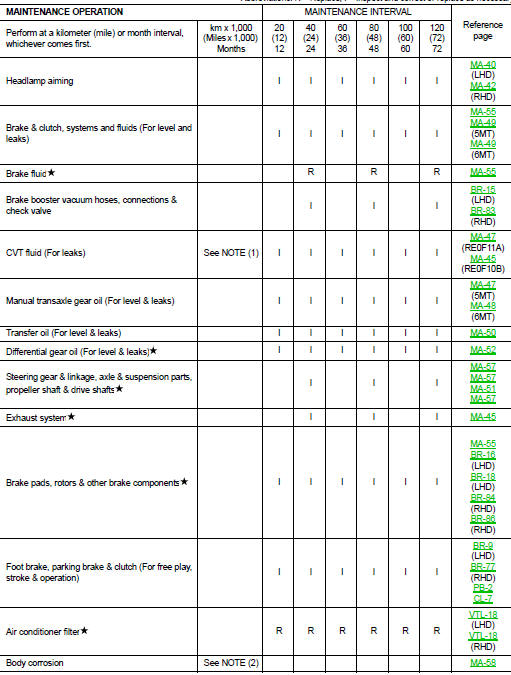

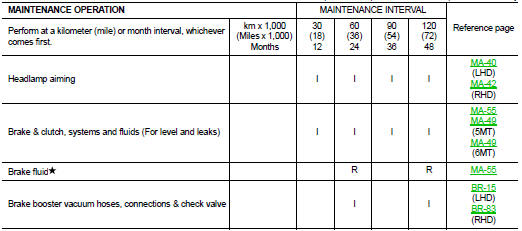

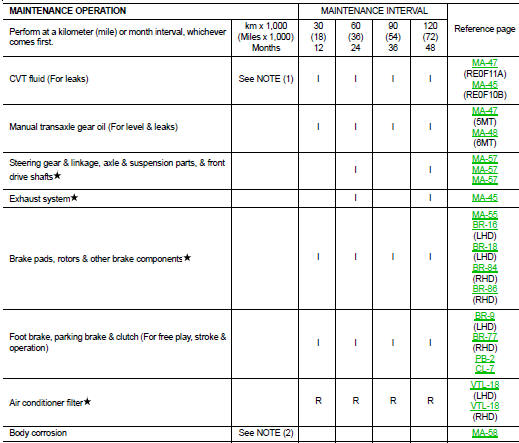

CHASSIS AND BODY MAINTENANCE (MR16DDT PETROL ENGINE)

Abbreviations: R = Replace, I = Inspect and correct or replace as necessary

NOTE

:

• Maintenance items with “ ” should be performed more frequently according to

“Maintenance under severe driving conditions”.

• (1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, inspect CVT fluid deterioration with CONSULT-III every 90,000 km (54,000 miles), then change CVT fluid NS-2 if necessary. And if CONSULT-III is not available, change (not just inspect) CVT fluid NS-2 every 90,000 km (54,000 miles).

Using transmission fluid other than Genuine NISSAN CVT Fluid NS-2 will damage the CVT, which is not covered by the warranty.

• (2) Inspect once per year.

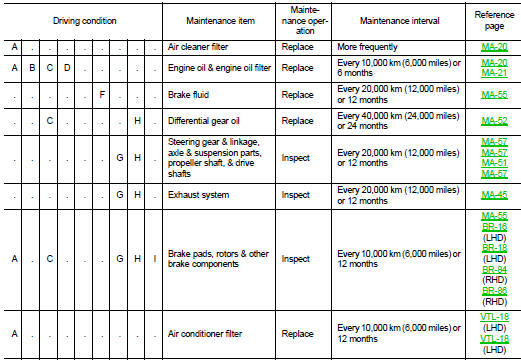

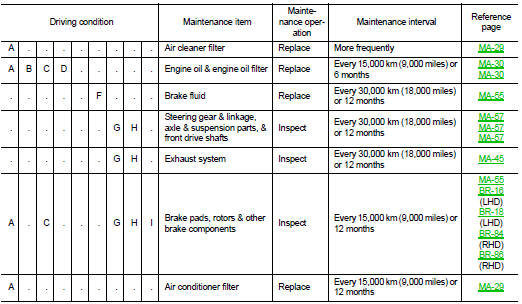

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS (MR16DDT PETROL ENGINE)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is mainly operated under severe driving conditions as shown below, more frequent maintenance must be performed on the following items as shown in the table.

Severe driving conditions

A — Driving under dusty conditions

B — Driving repeatedly short distances

C — Towing a trailer or caravan

D — Extensive idling

E — Driving in extremely adverse weather conditions or in areas where ambient

temperatures are either

extremely low or extremely high

F — Driving in high humidity or mountainous areas

G — Driving in areas using salt or other corrosive areas

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

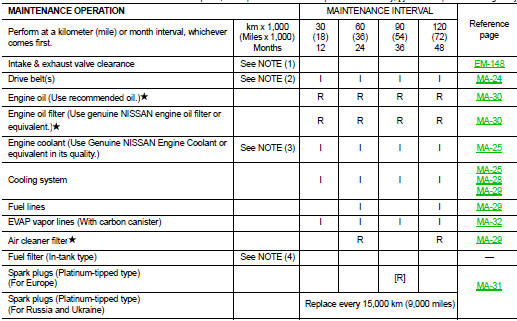

ENGINE AND EMISSION CONTROL MAINTENANCE (HR16DE PETROL ENGINE)

Abbreviations: R = Replace, I = Inspect and correct or replace as necessary, [ ] = At the specified mileage only

NOTE

:

• Maintenance items with “ ” should be performed more frequently according to

“Maintenance under severe driving conditions”.

• (1) Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

• (2) Replace the drive belt if found damaged.

• (3) Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to avoid possible aluminum corrosion within the engine cooling system caused by the use of non-genuine engine coolant. First replace at 90,000 km (54,000 miles)/60 months, then every 60,000 km (36,000 miles)/48 months. Perform “I” (Checking the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

• (4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

CHASSIS AND BODY MAINTENANCE (HR16DE PETROL ENGINE)

Abbreviations: R = Replace, I = Inspect and correct or replace as necessary

NOTE

:

• Maintenance items with “ ” should be performed more frequently according to

“Maintenance under severe driving conditions”.

• (1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, inspect CVT fluid deterioration with CONSULT-III every 90,000 km (54,000 miles), then change CVT fluid NS-2 if necessary. And if CONSULT-III is not available, change (not just inspect) CVT fluid NS-2 every 90,000 km (54,000 miles). Using transmission fluid other than Genuine NISSAN CVT Fluid NS-2 will damage the CVT, which is not covered by the warranty.

• (2) Inspect once per year.

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS (HR16DE PETROL ENGINE)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is mainly operated under severe driving conditions as shown below, more frequent maintenance must be performed on the following items as shown in the table.

Severe driving conditions

A — Driving under dusty conditions

B — Driving repeatedly short distances

C — Towing a trailer or caravan

D — Extensive idling

E — Driving in extremely adverse weather conditions or in areas where ambient

temperatures are either

extremely low or extremely high

F — Driving in high humidity or mountainous areas

G — Driving in areas using salt or other corrosive areas

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

General maintenance

General maintenance

General Maintenance

General maintenance includes those items which should be checked during the

normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operati ...

Recommended fluids and lubricants

Recommended fluids and lubricants

Fluids and Lubricants

*1: For additional information, see “SAE Viscosity Number”.

*2: Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to

avoid possible aluminium corrosi ...

Other materials:

P position warning does not operate

Diagnosis Procedure

1.CHECK DTC WITH BCM, TCM AND COMBINATION METER

Check that DTC is not detected with BCM, TCM and combination meter.

Is the inspection result normal?

YES >> GO TO 2.

NO-1 >> Refer to BCS-67, "DTC Index". (BCM)

NO-2 >> Refer to TM-171, "DT ...

P range interlock door lock/unlock function does not operate

Diagnosis Procedure

1.CHECK “AUTOMATIC LOCK/UNLOCK SELECT” SETTING IN “WORK SUPPORT”

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “AUTOMATIC LOCK/UNLOCK SELECT” in “WORK SUPPORT” mode.

3. Check “AUTOMATIC LOCK/UNLOCK SELECT” in “WORK SUPPORT”.

Refer to DLK-41, "DOOR LOCK : ...

Service data and specifications (SDS)

DRIVE BELT (MR16DDT)

DRIVE BELT (MR16DDT) : Drive Belt

DRIVE BELT

DRIVE BELT (HR16DE)

DRIVE BELT (HR16DE) : Drive Belt

DRIVE BELT

Belt Deflection

*: When engine is cold.

Belt Tension and Frequency

*: When engine is cold.

DRIVE BELT (K9K)

DRIVE BELT (K9K) : Drive Belt

DRIVE BELT ...