Nissan Juke Service and Repair Manual : P1550 battery current sensor

DTC Logic

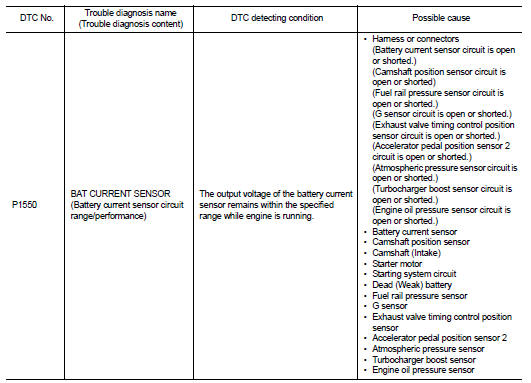

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more

than 8 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and wait at least 10 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-701, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

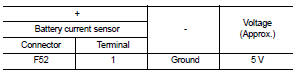

1.CHECK BATTERY CURRENT SENSOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect battery current sensor harness connector.

3. Turn ignition switch ON.

4. Check the voltage between battery current sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

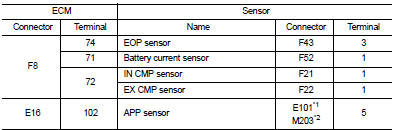

2.CHECK SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness connector for short to power and short to ground, between the following terminals.

*1: LHD models or RHD models with CVT *2: RHD models with M/T

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

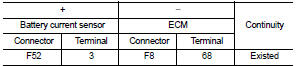

3.CHECK BATTERY CURRENT SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

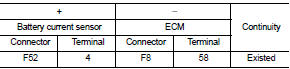

3. Check the continuity between battery current sensor harness connector and ECM harness connector.

4. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK BATTERY CURRENT SENSOR INPUT SIGNAL CIRCUIT

1. Check the continuity between battery current sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts 5.CHECK BATTERY CURRENT SENSOR

Check the battery current sensor. Refer to EC-702, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace battery negative cable assembly. Refer to PG-125, "Exploded View".

Component Inspection

1.CHECK BATTERY CURRENT SENSOR

1. Turn ignition switch OFF.

2. Reconnect harness connectors disconnected.

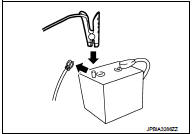

3. Disconnect battery negative cable.

4. Install jumper cable between battery negative terminal and body ground.

5. Turn ignition switch ON.

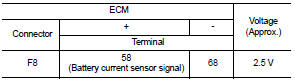

6. Check the voltage between ECM harness connector and ground.

Before measuring the terminal voltage, confirm that the battery is fully charged. Refer to PG-111, "How to Handle Battery".

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace battery negative cable assembly. Refer to PG-125, "Exploded View".

P1226 TP sensor

P1226 TP sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn

ignition switch OFF and wait at

least 10 se ...

P1551, P1552 battery current sensor

P1551, P1552 battery current sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following before conducting

the next ...

Other materials:

Insufficient heating

Description

Symptom

• Insufficient heating

• No warm air comes out. (Air flow volume is normal.)

Diagnosis Procedure

NOTE:

Perform self-diagnosis with CONSULT-III before performing symptom diagnosis. If

any malfunction result or

DTC is detected, perform the corresponding diagnosis.

1.CHE ...

LAN System can system (type 3)

DTC/circuit diagnosis

Main line between IPDM-E and DLC circuit

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose

connection (connector s ...

Lower Anchors and Tethers for CHildren System (LATCH)

LATCH label location

Your vehicle is equipped with special anchor points that are used with LATCH

(Lower Anchors and Tethers for CHildren) system compatible child restraints. This

system may also be referred to as the ISOFIX or ISOFIX compatible system. With this

system, you do not have to ...