Nissan Juke Service and Repair Manual : P0848 transmission fluid pressure SEN/SW B

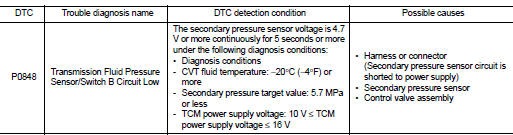

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, the ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT-III

With CONSULT-III

1. Start the engine.

2. Select “Data Monitor” in “TRANSMISSION”.

3. Select “FLUID TEMP”.

4. Maintain the following conditions for 10 seconds or more.

FLUID TEMP : −19°C (−2.2°F) or more

5. Check the first trip DTC.

With GST.

With GST.

1. Start the engine and wait for at least 10 seconds.

CAUTION:

When the ambient temperature is −20°C (−4°F) or less and the engine is cold,

warm up the engine

for approximately 5 minutes.

2. Check the first trip DTC.

Is “P0848”detected? YES >> Go to TM-428, "Diag

Diagnosis Procedure

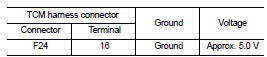

1.CHECK SECONDARY PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect the CVT unit connector.

3. Turn ignition switch ON.

4. Check the voltage between CVT unit harness connector terminal and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

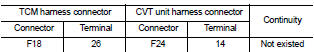

2.CHECK CIRCUIT BETWEEN TCM AND CVT UNIT

1. Turn the ignition switch OFF.

2. Disconnect the TCM connector.

3. Check the continuity between the TCM harness connector terminal and the CVT unit harness connector terminal.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace the malfunctioning parts.

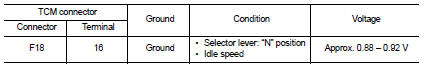

3.CHECK TCM INPUT SIGNALS

1. Connect all connectors removed.

2. Start the engine.

3. Check the voltage between TCM connector terminal and ground.

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> There is a malfunction of the secondary pressure sensor. Replace the transaxle assembly. Refer to TM-508, "Removal and Installation".

P0847 transmission fluid pressure SEN/SW B

P0847 transmission fluid pressure SEN/SW B

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for a ...

P0863 TCM communication

P0863 TCM communication

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for a ...

Other materials:

Trouble diagnosis - specification

value

Description

The specification (SP) value indicates the tolerance of the value that is

displayed in “SPEC” of “DATA MONITOR”

mode of CONSULT-III during normal operation of the Engine Control System. When

the value in “SPEC”

of “DATA MONITOR” mode is within the SP value, the Engine Control Sys ...

P0139 HO2S2

DTC Logic

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the air fuel ratio (A/F) sensor 1. The oxygen

storage capacity of the three way catalyst 1 causes the longer

switching time. To judge the malfunctions of heated oxygen sensor

2, ...

Meter buzzer circuit

Component Function Check

1.CHECK OPERATION OF METER BUZZER

1. Select “BUZZER” of “BCM” on CONSULT-III.

2. Perform “LIGHT WARN ALM” of “Active Test”.

Does meter buzzer beep?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK COMBINATION METER INPUT SIGNAL

Select the “Data Monitor” f ...