Nissan Juke Service and Repair Manual : P0712 transmission fluid temperature sensor A

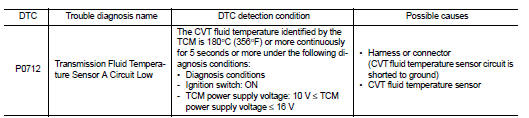

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start the engine and wait for 10 seconds or more.

2. Check the first trip DTC.

Is “P0712” detected? YES >> Go to TM-406, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

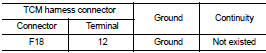

1.CHECK CIRCUIT BETWEEN TCM AND THE CVT UNIT

1. Turn ignition switch OFF.

2. Disconnect the TCM connector and the CVT unit connector.

3. Check the continuity between TCM harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace malfunctioning part.

2.CHECK CVT FLUID TEMPERATURE SENSOR

Check the CVT fluid temperature sensor. Refer to TM-406, "Component Inspection (CVT Fluid Temperature Sensor)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace the malfunctioning parts.

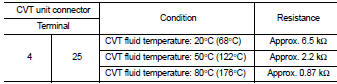

Component Inspection (CVT Fluid Temperature Sensor)

1.CHECK CVT FLUID TEMPERATURE SENSOR

Check resistance between the CVT unit connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> There is a malfunction of the CVT fluid temperature sensor. Replace the transaxle assembly.

Refer to TM-508, "Removal and Installation".

P0711 transmission fluid temperature sensor A

P0711 transmission fluid temperature sensor A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for a ...

P0713 transmission fluid temperature sensor A

P0713 transmission fluid temperature sensor A

DTC Logic

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for at

least 10 seconds, th ...

Other materials:

Timing chain

Exploded View

1. Timing chain slack guide

2. Timing chain tensioner

3. Timing chain

4. Oil pump drive chain

5. Crankshaft sprocket

6. Crankshaft key

7. Oil pump sprocket

8. Front cover

9. O-ring

10. O-ring

11. Oil control valve cover

12. O-ring

13. Oil control valve (EXH)

14 ...

The braking distance is long

Description

Brake stopping distance is long when ABS function is operated.

Diagnosis Procedure

CAUTION:

Brake stopping distance on slippery road like rough road, gravel road or snowy

road may become

longer when ABS is operated than when ABS is not operated.

1.CHECK BRAKING FORCE

Check bra ...

P0717 input speed sensor A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignition switch

OFF and wait at least 10 seconds before performing the next test.

After the repair, p ...