Nissan Juke Service and Repair Manual : P0525 ASCD system

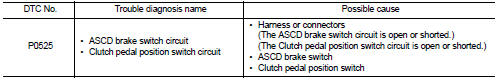

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF and wait at least 20 seconds.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

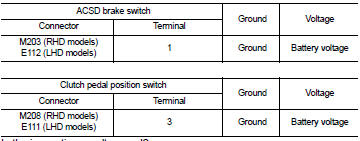

2.CHECK ASCD BRAKE SWITCH AND CLUTCH PEDAL POSITION SWITCH POWER SUPPLY CIRCUIT

1. Disconnect ACSD brake switch and clutch pedal position switch harness connectors.

2. Check the voltage between ACSD brake switch and clutch pedal position switch harness connectors and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

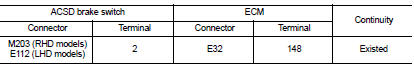

3.CHECK ASCD BRAKE SWITCH INPUT SIGNAL CIRCUIT AND CLUTCH PEDAL POSITION SWITCH GROUND CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between ACSD brake switch harness connector and ECM harness connector.

2. Check the continuity between clutch pedal position switch harness connector and ground.

3. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK ASCD BRAKE SWITCH AND CLUTCH PEDAL POSITION SWITCH

Refer to EC-959, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace ASCD brake switch or clutch pedal position switch.

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

Is the inspection result normal? YES >> Replace ACSD brake switch or clutch pedal position switch.

NO >> Repair or replace.

Component Inspection

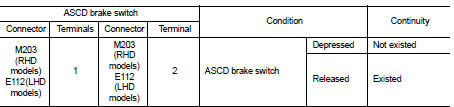

1.CHECK ASCD BRAKE SWITCH-I

1. Turn ignition switch OFF.

2. Disconnect ASCD brake switch harness connector.

3. Check the continuity between ASCD brake switch terminals under the following condition.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace ASCD brake switch.

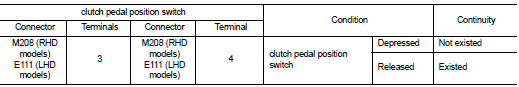

2.CHECK CLUTCH PEDAL POSITION SWITCH-I

1. Turn ignition switch OFF.

2. Disconnect clutch pedal position switch harness connector.

3. Check the continuity between clutch pedal position switch terminals under the following condition.

the inspection result normal? YES >> INSPECTION END

NO >> Replace clutch pedal position switch.

P0504 ASCD brake SWI

P0504 ASCD brake SWI

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF and wait at least 20 seconds.

2. Check ground connection E38. Refer to Ground inspection ...

P0530 refrigerant pressure sensor

P0530 refrigerant pressure sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

In ...

Other materials:

Additional service when replacing control unit

Description

When the control unit replaced, the initialization in necessary for normal

operation of power window system.

CAUTION:

The following specified operations can not be performed under the

non-initialized condition.

• Auto-up operation

• Anti-pinch function

Work Procedure

1.SYSTE ...

Diagnosis system (BCM) (with intelligent key system)

Description

Air conditioning system performs self-diagnosis, operation check, function

diagnosis, and various settings

using diagnosis function of each control unit.

Common item : consult-III Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN ...

P0530 refrigerant pressure sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or ...