Nissan Juke Service and Repair Manual : P0444 EVAP canister purge volume control solenoid valve

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm battery voltage is more than

11 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for at least 13 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-283, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect EVAP canister purge volume control solenoid valve harness connector.

3. Turn ignition switch ON.

4. Check the voltage between EVAP canister purge volume control solenoid valve harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector.

3. Check the continuity between EVAP canister purge volume control solenoid valve harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground.

Is the inspection result normal? YES-1 >> With CONSULT-III: GO TO 4.

YES-2 >> Without CONSULT-III: GO TO 5.

NO >> Repair or replace error-detected parts.

3.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EVAP canister purge volume control solenoid valve harness connector and ECM harness connector.

4. Also check harness for short to power.

Is the inspection result normal? YES-1 >> With CONSULT-III: GO TO 4.

YES-2 >> Without CONSULT-III: GO TO 5.

NO >> Repair or replace error-detected parts.

4.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

With CONSULT-III

With CONSULT-III

1. Reconnect all harness connectors disconnected.

2. Start engine.

3. Perform “PURG VOL CONT/V” in “ACTIVE TEST” mode of “ENGINE” using CONSULT-III.

4. Check that engine speed varies according to the valve opening.

Does engine speed vary according to the valve opening? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> GO TO 5.

5.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Check the EVAP canister purge volume control solenoid valve. Refer to EC-284, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace EVAP canister purge volume control solenoid valve. Refer to EM-28, "Exploded View".

Component Inspection

1.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT-III

With CONSULT-III

1. Turn ignition switch OFF.

2. Reconnect all harness connectors disconnected.

3. Disconnect EVAP purge hoses connected to EVAP canister purge volume control solenoid valve.

4. Turn ignition switch ON.

5. Select “PURG VOL CONT/V” in “ACTIVE TEST” mode of “ENGINE” using CONSULT-III.

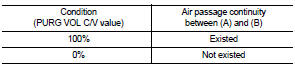

6. Touch “Qd” and “Qu” on CONSULT-III screen to adjust “PURG VOL C/V” opening and check air passage continuity of EVAP canister purge volume control solenoid valve as per the following conditions.

Without CONSULT-III

Without CONSULT-III

1. Turn ignition switch OFF.

2. Disconnect EVAP canister purge volume control solenoid valve harness connector.

3. Disconnect EVAP purge hoses connected to EVAP canister purge volume control solenoid valve.

4. Check air passage continuity of EVAP canister purge volume control solenoid valve as per the following conditions.

YES >> INSPECTION END

NO >> Replace EVAP canister purge volume control solenoid valve. Refer to EM-28, "Exploded View".

P0420 three way catalyst function

P0420 three way catalyst function

DTC Logic

DTC DETECTION LOGIC

The ECM monitors the switching frequency ratio of air fuel ratio (A/F)

sensor 1 and heated oxygen sensor 2.

A three way catalyst (manifold) with high oxygen storage ...

P0500 VSS

P0500 VSS

Description

ECM receives vehicle speed signals from two different paths via CAN

communication line: One is from the

ABS actuator and electric unit (control unit) via the combination unit and the

...

Other materials:

Engine emits blue smoke

Description

CHART 19: ENGINE EMITS BLUE SMOKE

Diagnosis Procedure

1.CHECK ENGINE OIL

Check the grade of engine oil. Refer to LU-33, "Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace engine oil. Refer to LU-34, "Refilling".

2.CH ...

B2205 vehicle speed

Description

Vehicle speed signal is transmitted from ABS actuator and electric unit

(control unit) via CAN communication

to combination meter.

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.PERFORM SELF-DIAGNOSIS OF ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Perform “Self Diagnost ...

Door does not lock/unlock with door lock and unlock

switch

All door

ALL DOOR : Description

All doors do not lock/unlock using door lock and unlock switch.

ALL DOOR : Diagnosis Procedure

1.CHECK DOOR LOCK AND UNLOCK SWITCH

Check door lock and unlock switch.

Refer to DLK-79, "DRIVER SIDE : Component Function Check".

Is the inspection resu ...