Nissan Juke Service and Repair Manual : P0102, P0103 MAF sensor

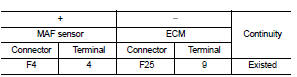

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

Which DTC is detected? P0102 >> GO TO 2.

P0103 >> GO TO 3.

2.PERFORM DTC CONFIRMATION PROCEDURE FOR DTC P0102

1. Start engine and wait at least 5 seconds.

2. Check DTC.

Is DTC detected? YES >> Proceed to EC-189, "Diagnosis Procedure".

NO >> INSPECTION END 3.PERFORM DTC CONFIRMATION PROCEDURE FOR DTC P0103-I

1. Turn ignition switch ON and wait at least 5 seconds.

2. Check DTC.

Is DTC detected? YES >> Proceed to EC-189, "Diagnosis Procedure".

NO >> GO TO 4.

4.PERFORM DTC CONFIRMATION PROCEDURE FOR DTC P0103-II

1. Start engine and wait at least 5 seconds.

2. Check DTC.

Is DTC detected? YES >> Proceed to EC-189, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.INSPECTION START

Confirm the detected DTC.

Which DTC is detected? P0102 >> GO TO 2.

P0103 >> GO TO 3.

2.CHECK INTAKE SYSTEM

Check the following for connection.

• Air duct

• Vacuum hoses

• Intake air passage between air duct to intake manifold

Is the inspection result normal? YES >> GO TO 3.

NO >> Reconnect the parts. Refer to EM-26, "Exploded View".

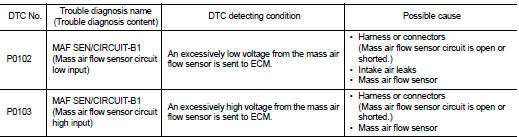

3.CHECK MAF SENSOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect mass air flow (MAF) sensor harness connector.

3. Turn ignition switch ON.

4. Check the voltage between MAF sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

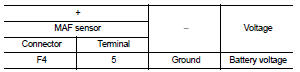

4.CHECK MAF SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector.

3. Check the continuity between MAF sensor harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

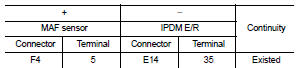

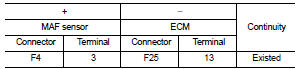

5.CHECK MAF SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between MAF sensor harness connector and ECM harness connector.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.CHECK MAF SENSOR INPUT SIGNAL CIRCUIT

1. Check the continuity between MAF sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

7.CHECK MASS AIR FLOW SENSOR

Check the mass air flow sensor. Refer to EC-191, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace mass air flow sensor. Refer to EM-26, "Exploded View".

Component Inspection

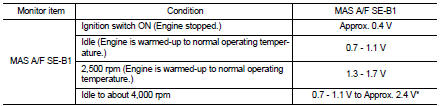

1.CHECK MASS AIR FLOW SENSOR-I

With CONSULT-III

With CONSULT-III

1. Turn ignition switch OFF.

2. Reconnect all harness connectors disconnected.

3. Start engine and warm it up to normal operating temperature.

4. Connect CONSULT-III and select “DATA MONITOR” mode of “ENGINE”.

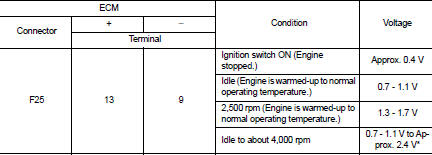

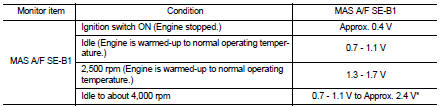

5. Select “MAS A/F SE-B1” and check indication.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

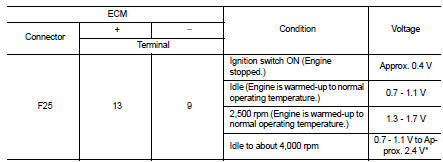

Without CONSULT-III

Without CONSULT-III

1. Turn ignition switch OFF.

2. Reconnect all harness connectors disconnected.

3. Start engine and warm it up to normal operating temperature.

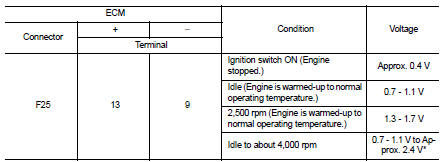

4. Check the voltage between ECM harness connector and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK FOR THE CAUSE OF UNEVEN AIR FLOW THROUGH MASS AIR FLOW SENSOR

1. Turn ignition switch OFF.

2. Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

- Crushed air ducts

- Malfunctioning seal of air cleaner element

- Uneven dirt of air cleaner element

- Improper specification of intake air system parts

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK MASS AIR FLOW SENSOR-II

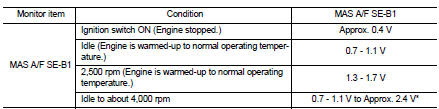

With CONSULT-III

With CONSULT-III

1. Repair or replace malfunctioning part.

2. Start engine and warm it up to normal operating temperature.

3. Connect CONSULT-III and select “DATA MONITOR” mode of “ENGINE”.

4. Select “MAS A/F SE-B1” and check indication.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Without CONSULT-III

Without CONSULT-III

1. Repair or replace malfunctioning part.

2. Start engine and warm it up to normal operating temperature.

3. Check the voltage between ECM harness connector and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 4.

4.CHECK MASS AIR FLOW SENSOR-III

With CONSULT-III

With CONSULT-III

1. Turn ignition switch OFF.

2. Disconnect mass air flow sensor harness connector and reconnect it again.

3. Start engine and warm it up to normal operating temperature.

4. Connect CONSULT-III and select “DATA MONITOR” mode of “ENGINE”.

5. Select “MAS A/F SE-B1” and check indication.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Without CONSULT-III

Without CONSULT-III

1. Turn ignition switch OFF.

2. Disconnect mass air flow sensor harness connector and reconnect it again.

3. Start engine and warm it up to normal operating temperature.

4. Check the voltage between ECM harness connector and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Is the inspection result normal? YES >> INSPECTION END

NO >> Clean or replace mass air flow sensor. Refer to EM-26, "Exploded View".

P0097, P0098 IAT sensor 2

P0097, P0098 IAT sensor 2

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

P0107, P0108 atmospheric pressure

sensor

P0107, P0108 atmospheric pressure

sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conducti ...

Other materials:

Refilling

1. Remove filler plug (1) and gasket from transaxle case.

2. Fill with new gear oil until oil level reaches the specified limit at

filler plug mounting hole as shown in the figure.

Oil grade and

viscosity

: Refer to MA-13, "Fluids and Lubricants".

Oil capacity : Refer to TM-63, " ...

Removal and Installation

REMOVAL

1. Remove engine assembly. Refer to EM-55, "2WD : Exploded View" (2WD) ,

EM-59, "4WD : Exploded

View" (4WD).

2. Remove oil pan (lower). Refer to EM-41, "Removal and Installation".

3. Remove front cover, and other related parts. Refer to EM-67, "Explod ...

Hood lock

Exploded View

1. Hood lock control cable assembly

2. Hood lock assembly

: Clip

: N·m (kg-m, ft-lb)

: Body grease

Hood lock

HOOD LOCK : Removal and Installation

REMOVAL

1. Remove front center grille. Refer to EXT-18, "Removal and Installation".

2. Remove crash zone sensor. Refe ...