Nissan Juke Service and Repair Manual : Oil seal

Valve oil seal

VALVE OIL SEAL : Removal and Installation

REMOVAL

1. Remove camshafts. Refer to EM-191, "Exploded View".

2. Remove valve lifters. Refer to EM-191, "Exploded View".

3. Rotate crankshaft, and set piston whose valve oil seal is to be removed to TDC. This will prevent valve from dropping into cylinder.

CAUTION:

When rotating crankshaft, be careful to avoid scarring front cover with timing

chain.

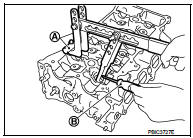

4. Remove valve collet.

• Compress valve spring with the valve spring compressor [SST: KV10116200] (A), the attachment [SST: KV10115900] (C), and the adapter [SST: KV10109220] (B). Remove valve collet with magnet hand.

CAUTION:

Be careful not to damage valve lifter holes.

5. Remove valve spring retainer and valve spring (with valve spring seat).

CAUTION:

Never remove valve spring seat from valve spring.

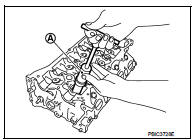

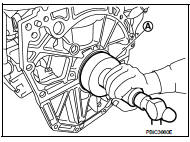

6. Remove valve oil seal with the valve oil seal puller [SST: KV10107902] (A).

INSTALLATION

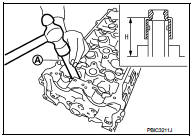

1. Apply new engine oil to valve oil seal joint surface and seal lip.

2. Press in valve oil seal to the height (H) shown in the figure with the valve oil seal drift [SST: KV10115600] (A).

Height (H) : 13.2 - 13.8 mm (0.520 - 0.543 in)

3. Install in the reverse order of removal, for the rest of parts.

Front oil seal

FRONT OIL SEAL : Removal and Installation

REMOVAL

1. Remove the following parts.

• Remove fillet mold : Refer to EXT-26, "Exploded View" • Front fender protector (RH): Refer to EXT-22, "Exploded View".

• Drive belt: Refer to EM-155, "Removal and Installation".

• Crankshaft pulley: Refer to EM-181, "Exploded View".

2. Remove front oil seal with a suitable tool.

CAUTION:

Be careful not to damage front cover and crankshaft

.

INSTALLATION

1. Apply new engine oil to new front oil seal joint surface and seal lip.

2. Install front oil seal so that each seal lip is oriented as shown in the figure.

A : Dust seal lip

B : Oil seal lip

: Engine outside

: Engine outside

: Engine inside

: Engine inside

• Press-fit front oil seal using a suitable drift with outer diameter 50 mm (1.97 in) and inner diameter 44 mm (1.73 in).

CAUTION:

• Be careful not to damage front cover and crankshaft.

• Press-fit oil seal straight to avoid causing burrs or tilting.

3. Install in the reverse order of removal, for the rest of parts.

Rear oil seal

REAR OIL SEAL : Removal and Installation

REMOVAL

1. Remove transaxle assembly. Refer to TM-30, "Exploded View" (M/T models), TM-508, "Exploded View" (CVT models).

2. Remove clutch cover and clutch disk (M/T models). Refer to CL-29, "EXCEPT FOR K9K : Exploded View".

3. Remove flywheel (M/T models) or drive plate (CVT models). Refer to EM-227, "Exploded View".

4. Remove rear oil seal with a suitable tool.

CAUTION:

Be careful not to damage crankshaft and cylinder block.

INSTALLATION

1. Apply the liquid gasket lightly to entire outside area of new rear oil seal.

Use Genuine Liquid Gasket or equivalent.

2. Install rear oil seal so that each seal lip is oriented as shown in the figure.

A : Dust seal lip

B : Oil seal lip

: Engine outside

: Engine outside

: Engine inside

: Engine inside

• Press-fit rear oil seal with a suitable drift (A) outer diameter 113 mm (4.45 in) and inner diameter 90 mm (3.54 in).

CAUTION:

• Be careful not to damage crankshaft and cylinder block.

• Press-fit oil seal straight to avoid causing burrs or tilting.

• Never touch grease applied onto oil seal lip.

• Press in rear oil seal (1) to the position as shown in the figure.

A : Rear end surface of cylinder block b : 0 - 0.5 mm (0 - 0.020 in)

3. Install in the reverse order of removal, for the rest of parts.

Camshaft

Camshaft

Exploded View

1. Camshaft bracket (No. 2 to 5)

2. Camshaft bracket (No. 1)

3. Camshaft sprocket (EXH)

4.Exhaust valve timing control solenoid

valve

5. O-ring

6.Camshaft sprocket (INT)

7. ...

Cylinder head

Cylinder head

Exploded View

REMOVAL

1. Cylinder head assembly

2. Cylinder head bolt

3. Washer

4. Cylinder head gasket

A.Tightening must be done following the installation procedure.

Refer to EM-209

: ...

Other materials:

P0606 ECM

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.INSPECTION START

1. Turn ignition switch ON.

2. Erase DTC.

3. Turn ignition switch OFF and wait for 20 seconds.

4. Turn ignition switch ON and perform the self-diagnosis.

Is the DTC P0606 displayed again?

YES >> GO TO 2.

NO &g ...

Door lock operation warning does not operate

Diagnosis Procedure

1.CHECK DOOR LOCK FUNCTION

Check door lock function.

Does door lock/unlock using door request switch?

YES >> GO TO 2.

NO >> Refer to DLK-256, "Component Function Check".

2.CHECK INTELLIGENT KEY WARNING BUZZER

Check Intelligent Key warning buzzer ...

If your vehicle overheats

CAUTION

• Do not continue to drive if your vehicle overheats. Doing so could cause

engine damage or a vehicle fire.

• To avoid the danger of being scalded, never remove the radiator cap while the

engine is still hot.

When the radiator cap is removed, pressurized hot water will spurt out, poss ...