Nissan Juke Service and Repair Manual : Headlamp washer circuit

Component Function Check

1.CHECK HEADLAMP WASHER OPERATION

CONSULT-III ACTIVE TEST

CONSULT-III ACTIVE TEST

1. Select “HEAD LAMP WASHER” of IPDM E/R active test item.

2. With operating the test item, check headlamp operation.

On :Headlamp washer ON operation Off :Stop the headlamp washer.

Is headlamp washer operation normally? YES >> Headlamp washer circuit is normal.

NO >> Refer to WW-50, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK HEADLAMP WASHER FUSIBLE LINK

1. Turn the ignition switch OFF.

2. Check that the headlamp washer 30A fusible link (#L) is not fusing.

Is the fusible link fusing? YES >> Replace the fusible link after repairing the applicable circuit.

NO >> GO TO 2.

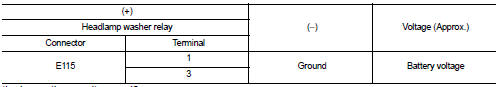

2.CHECK HEADLAMP WASHER RELAY POWER SUPPLY

1. Remove headlamp washer relay.

2. Check voltage between headlamp washer relay harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair harnesses or connectors.

3.CHECK HEADLAMP WASHER RELAY

Check headlamp washer relay. Refer to WW-49, "Component Inspection".

Is the headlamp washer relay normal? YES >> GO TO 4.

NO >> Replace headlamp washer relay.

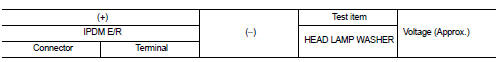

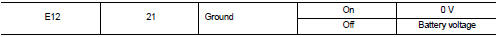

4.CHECK HEADLAMP WASHER RELAY CONTROL SIGNAL

CONSULT-III ACTIVE TEST

CONSULT-III ACTIVE TEST

1. Turn the ignition switch OFF.

2. Install headlamp washer relay.

3. Turn the ignition switch ON.

4. Select “HEAD LAMP WASHER” of IPDM E/R active test item.

5. With operating the test item, check voltage between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> GO TO 7.

Fixed at 0 V >> GO TO 5.

Fixed at battery voltage >>Replace IPDM E/R.

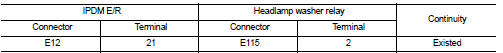

5.CHECK HEADLAMP WASHER RELAY CONTROL SIGNAL OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Remove headlamp washer relay.

3. Disconnect IPDM E/R harness connector.

4. Check continuity between IPDM E/R harness connector and headlamp washer relay harness connector.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair the harnesses or connectors.

6.CHECK HEADLAMP WASHER RELAY CONTROL SIGNAL SHORT CIRCUIT

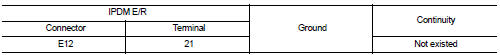

Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> Repair the harnesses or connectors.

NO >> Replace IPDM E/R.

7.CHECK HEADLAMP WASHER PUMP OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Remove headlamp washer relay.

3. Disconnect headlamp washer pump connector.

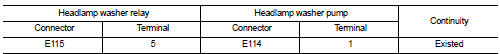

4. Check continuity between headlamp washer relay harness connector and headlamp washer pump harness connector.

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair the harnesses or connectors.

8.CHECK HEADLAMP WASHER PUMP (GND) OPEN CIRCUIT

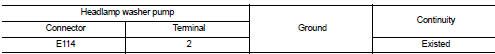

Check continuity headlamp washer pump harness connector and ground.

Is the inspection result normal? YES >> Replace headlamp washer pump.

NO >> Repair the harnesses or connectors.

Headlamp washer relay

Headlamp washer relay

Component Inspection

1.CHECK HEADLAMP WASHER RELAY

1. Turn the ignition switch OFF.

2. Remove headlamp washer relay.

3. Apply battery voltage to headlamp washer relay between terminals 1 and 2.

4 ...

Wiper and washer system

Wiper and washer system

Wiring Diagram - WIPER AND WASHER SYSTEM -

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, " ...

Other materials:

Symptom diagnosis

Squeak and rattle trouble diagnoses

Work Flow

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist

when the noise occurs. Use the Diagnostic

Worksheet during the interview to document the facts and conditions when the

noise occurs and any of

the cu ...

Condenser

Exploded View

1. Condenser

2. Condenser lower bracket RH

3. Condenser lower bracket LH

4. O-ring

5. Liquid tank braket

6. Liquid tank

7. Braket

8. O-ring

9. Refrigerant pressure sensor

: Do not reuse

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

Condenser : Removal and Installation

C ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT

PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...