Nissan Juke Service and Repair Manual : G sensor

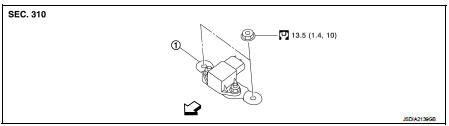

Exploded View

1. G sensor

: Vehicle front

: Vehicle front

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

Removal and Installation

CAUTION:

• Never drop or strike G sensor, because it has little tolerance for impact.

• Never use a power tool to avoid impact.

REMOVAL

1. Disconnect the battery cable from the negative terminal. Refer to PG-124, "Removal and Installation".

2. Remove driver seat (LHD) or passenger seat (RHD). Refer to SE-19, "Removal and Installation".

3. Remove center pillar lower garnish (left side) and dash side finisher (left side). Refer to INT-20, "CENTER PILLAR LOWER GARNISH : Removal and Installation" (center pillar lower garnish) and INT-20, "DASH SIDE FINISHER : Removal and Installation" (dash side finisher).

4. Pull up floor carpet. Refer to INT-23, "Removal and Installation".

5. Disconnect G sensor harness connector.

6. Remove G sensor.

7. Remove bracket.

INSTALLATION

Installation is the reverse order of removal.

Adjustment

ADJUSTMENT AFTER INSTALLATION

Perform “G SENSOR CALIBRATION”. Refer to TM-377, "Description".

Air breather hose

Air breather hose

Removal and Installation

REMOVAL

1. Remove air cleaner case. Refer to EM-26, "Removal and Installation".

2. Remove clip from bracket.

3. Remove air breather hose from transaxle assembly. ...

Control valve

Control valve

Exploded View

COMPONENT PARTS LOCATION

1. Transaxle assembly

2. Control valve

3. Bracket

4. O-ring

5. Oil strainer assembly

6. Magnet

7. Drain plug gasket

8. Drain plug

9. Oil pan mo ...

Other materials:

Does not operate

Description

ABS function and EBD function does not operate.

Diagnosis Procedure

CAUTION:

ABS function and EBD function never operate when the vehicle speed is 10 km/h

(6.2 MPH) or less.

1.CHECK ABS WARNING LAMP

Check that ABS warning lamp and brake warning lamp turn ON and turn OFF

appro ...

Electric foldable door mirror does not operate

Diagnosis Procedure

1.CHECK DOOR MIRROR (OPEN/CLOSE MOTOR) CIRCUIT

Check door mirror (open/close motor) circuit.

Refer to MIR-25, "Component Function Check".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CONF ...

Front seat-mounted side-impact supplemental air bag and roof-mounted curtain

side-impact supplemental air bag systems

The side air bags are located in the outside of the seatback of the front seats.

The curtain air bags are located in the side roof rails. All of the information,

cautions and warnings in this manual still apply and must be followed.

The side air bags and curtain air bags are designed to infla ...