Nissan Juke Service and Repair Manual : Front fender

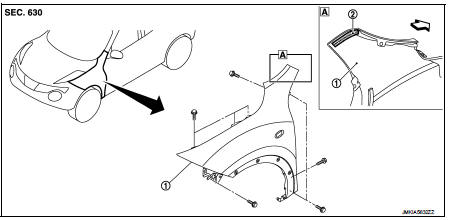

Exploded View

1. Front fender assembly 2. Front fender stiffener

: Vehicle front

: Vehicle front

Removal and Installation

REMOVAL

1. Remove front fillet molding. Refer to EXT-26, "FRONT FILLET MOLDING : Removal and Installation".

2. Remove front bumper fascia assembly. Refer to EXT-13, "Removal and Installation".

3. Remove sill cover. Refer to EXT-23, "Removal and Installation".

4. Remove fender protector. Refer to EXT-22, "Removal and Installation".

5. Remove front fender cover. Refer to EXT-20, "Exploded View".

6. Remove front combination lamp. Refer to EXL-91, "Removal and Installation".

7. Remove side turn signal lamp. Refer to EXL-98, "Removal and Installation".

8. Remove mounting bolts of front fender assembly.

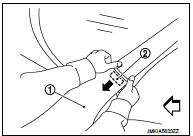

9. Remove front fender stiffener (2) from the vehicle body while carefully pulling upper portion of front fender (1) toward vehicle outside.

: Vehicle front

: Vehicle front

10. Remove front fender assembly.

CAUTION:

An viscous urethane foam is installed on the back surface of front fender. When

removing the

front fender, be careful to not deform the front fender while performing the

procedure and removing

the viscous urethane foam a little at a time.

INSTALLATION

Note the following items, and install in the reverse order of removal.

CAUTION:

• After installation, apply the touch-up paint (the body color) onto the head of

front fender mounting

bolts.

• After installation, adjust the following part.

- Hood assembly: Refer to DLK-556, "HOOD ASSEMBLY : Adjustment".

- Front door: Refer to DLK-570, "DOOR ASSEMBLY : Adjustment".

Radiator core supporT

Radiator core supporT

HR16DE

HR16DE : Exploded View

1. Radiator core support upper

2. Air guide RH (MT models)

3. Radiator core support lower

4. Air guide LH

5. Air guide (upper)

6. Air guide LH (CVT models)

...

Front door

Front door

Exploded View

1. Front door panel

2. Grommet

3. TORX bolt

4. Door striker

5. Door pad

6. Bumper rubber

7. Door check link

8. Door hinge (lower)

9. Door hinge (upper)

10. Grommet

: D ...

Other materials:

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT

PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver a ...

Diagnosis system (EPS control unit)

Consult-III Function

FUNCTION

CONSULT-III can display each diagnostic item using the diagnostic test modes

shown following.

*: The following diagnosis information is erased by erasing.

• DTC

• Freeze frame data (FFD)

ECU IDENTIFICATION

Displays the part number stored in the control unit.

...

B2562 low voltage

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.DTC CONFIRMATION

1. Erase DTC.

2. Turn ignition switch OFF.

3. Perform the “Self Diagnostic Result” of BCM with CONSULT-III, when passed 120

seconds or more after

the ignition switch is turned ON.

Is any DTC detected?

YES > ...