Nissan Juke Service and Repair Manual : Evaporative emission system

Inspection

1. Visually inspect EVAP vapor lines for improper attachment and for cracks, damage, loose connections, chafing and deterioration.

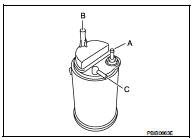

2. Check EVAP canister as follows: a. Block port (B). Orally blow air through port (A).

Check that air flows freely through port (C).

b. Block port (A). Orally blow air through port (B).

Check that air flows freely through port (C).

3. Visually inspect the fuel check valve for cracks, damage, loose connections chafing and deterioration.

4. Check fuel check valve as follows: a. Blow air through connector on the fuel tank side. A considerable resistance should be felt and a portion of air flow should be directed toward the EVAP canister side.

b. Blow air through connector on EVAP canister side. Air flow should be smoothly directed toward fuel tank side.

c. If fuel check valve is suspected or not properly functioning in step 1 and 2 above, replace it.

5. Inspect fuel tank filler cap vacuum relief valve for clogging, sticking, etc.

a. Wipe clean valve housing.

b. Check valve opening pressure and vacuum.

Pressure:

15.3 - 20.0 kPa (0.153 - 0.200 bar, 0.156 - 0.204 kg/

cm2, 2.22 - 2.90 psi)

Vacuum:

–6.0 to –3.4 kPa (–0.06 bar to –-0.034bar, –0.061 to –

0.035 kg/cm2, –0.87 to –0.49 psi)

c. If out of specification, replace fuel filler cap as an assembly

Ignition timing

Ignition timing

Description

This describes how to check the ignition timing. For the actual procedure,

follow the instructions in “BASIC

INSPECTION”.

Special Repair Requirement

1.CHECK IGNITION TIMING

1. Attac ...

Positive crankcase ventilation

Positive crankcase ventilation

Inspection

1.CHECK PCV VALVE

With engine running at idle, remove PCV valve from rocker cover. A

properly working valve makes a hissing noise as air passes through

it. A strong vacuum should be fel ...

Other materials:

B2618 BCM

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B2618 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

BCS-83, "DTC Logic".

• If DTC B2618 is displayed with DTC U1010, first perform the trouble diagnosis

for DTC U1010. Refer to

BCS-84, "D ...

Brake pad wear warning

The disc brake pads have audible wear warnings.

When a brake pad requires replacement, it will make a high pitched scraping sound

when the vehicle is in motion. This scraping sound will first occur only when the

brake pedal is depressed. After more wear of the brake pad, the sound will always

...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT

PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...