Nissan Juke Service and Repair Manual : Engine oil

Inspection

ENGINE OIL LEVEL

NOTE

:

Before starting engine, put vehicle horizontally and check the engine oil level.

If engine is already started, stop

it and allow 10 minutes before checking.

1. Pull out oil level gauge and wipe it clean.

2. Insert oil level gauge and check that the engine oil level is within the range (A) shown in the figure.

3. If it is out of range, adjust it.

ENGINE OIL APPEARANCE

• Check engine oil for white turbidity or heavy contamination.

• If engine oil becomes turbid and white, it is highly probable that it is contaminated with engine coolant.

Repair or replace damaged parts.

ENGINE OIL LEAKAGE

Check for engine oil leakage around the following area.

• Oil pan (upper and lower)

• Oil pan drain plug

• Oil pressure switch

• Oil filter

• Valve timing control cover

• Front cover

• Mating surface between cylinder head and camshaft bracket

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seals (front and rear)

OIL PRESSURE CHECK

WARNING:

• Be careful not to get burned, as engine oil may be hot.

• When checking engine oil pressure, shift position should be “Parking position”, and apply parking brake securely.

1. Check engine oil level. Refer to LU-8, "Inspection".

2. Disconnect harness connector at oil pressure sensor (1), and remove oil pressure switch using a deep socket (commercial service tool).

2 : Starter motor

: Engine front

: Engine front

CAUTION:

Never drop or shock oil pressure switch.

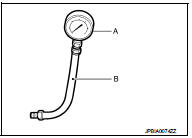

![3. Install oil pressure gauge [SST: ST25051001 (J-25695-1)] (A)](images/books/335/8/index.29.jpg)

3. Install oil pressure gauge [SST: ST25051001 (J-25695-1)] (A) and hose [SST: ST25052000 (J-25695-2)] (B).

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load.

NOTE

:

When engine oil temperature is low, engine oil pressure becomes high.

Engine oil pressure : Refer to LU-18, "Engine Oil Pressure".

If difference is extreme, check oil passage and oil pump for oil leakage.

6. After the inspections, install oil pressure switch as follows: a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to specification.

Use Genuine RTV Silicon Sealant or equivalent.

Tightening torque : Refer to EM-103, "Exploded View".

c. Check engine oil level. Refer to LU-8, "Inspection".

d. After warming up engine, check that there is no leakage of engine oil with running engine.

Draining

WARNING:

• Be careful not to get burned, as engine oil may be hot.

• Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as soon as possible

.

1. Warm up the engine, and check for engine oil leakage from engine components. Refer to LU-8, "Inspection".

2. Stop the engine and wait for 10 minutes.

3. Loosen oil filler cap.

4. Remove drain plug and then drain engine oil.

Refilling

1. Install drain plug with new drain plug washer. Refer to EM-40, "Exploded View".

CAUTION:

Be sure to clean drain plug and install with new drain plug washer.

Tightening torque : Refer to EM-40, "Exploded View".

2. Refill with new engine oil.

Engine oil specification and viscosity: Refer to MA-13, "Fluids and Lubricants".

Engine oil capacity : Refer to LU-18, "Periodical Maintenance Specification".

CAUTION:

• The refill capacity depends on the engine oil temperature and drain time. Use

these specifications

for reference only.

•Always use oil level gauge to determine the proper amount of engine oil in the engine.

3. Warm up engine and check area around drain plug and oil filter for engine oil leakage.

4. Stop engine and wait for 10 minutes.

5. Check the engine oil level. Refer to LU-8, "Inspection".

Oil filter

Oil filter

Removal and Installation

REMOVAL

1. Remove engine under cover.

2. Using oil filter wrench [SST: KV10115801 (J-38956)] (A), remove

oil filter.

: Vehicle front

CAUTION:

• Oil filter is provided w ...

Other materials:

P1611 ID discord, IMMU-ECM

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check DTC in “Self Diagnostic Result” mode of “ENGINE” using CONSULT-III.

Is DTC detected?

YES >> Go to SEC-53, "Diagnosis Procedure".

NO >> ...

Control linkage

Exploded View

1. Bracket

2. Selector cable

3. Shifter lever A

4. Selector lever

5. Cable mounting bracket

6. Tapping bolt

7. Shifter cable

8. Grommet

9. M/T shift selector assembly

10. Shifter lever

11. Shifter lever knob

: Always replace after every

disassembly.

: N·m (kg-m, ...

Audio operation precautions

Radio

Place the ignition switch in the ACC or ON position and push the PWR (power/VOL

(volume)) control to turn on the radio. If you listen to the radio with the engine

not running, the ignition switch should be placed in the ACC position.

Radio reception is affected by station signal strength ...