Nissan Juke Service and Repair Manual : Ecu diagnosis informatioN

TCM

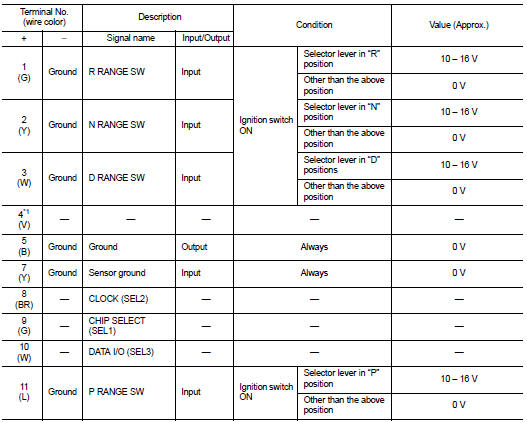

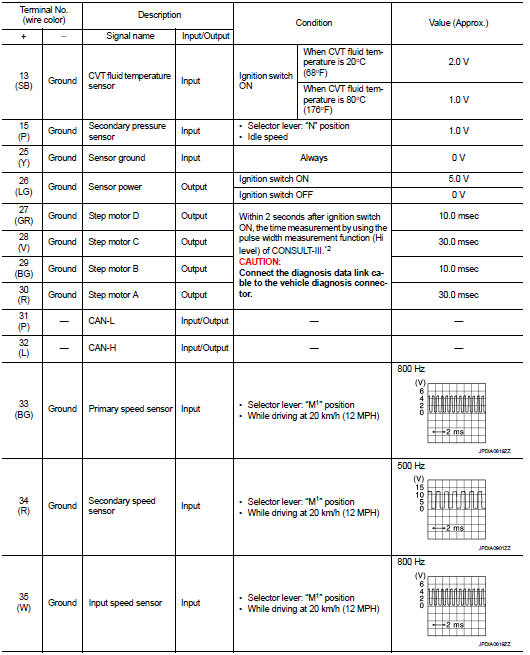

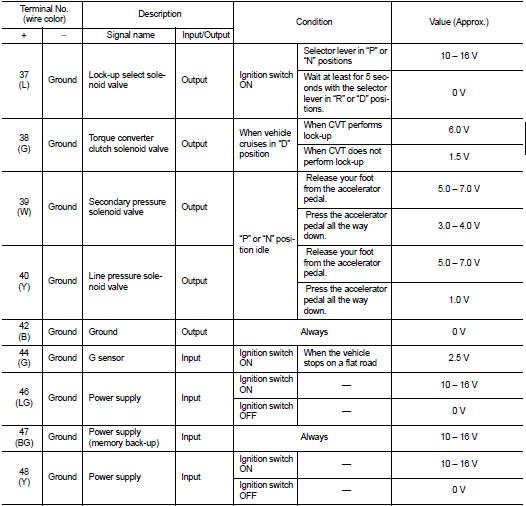

Reference Value

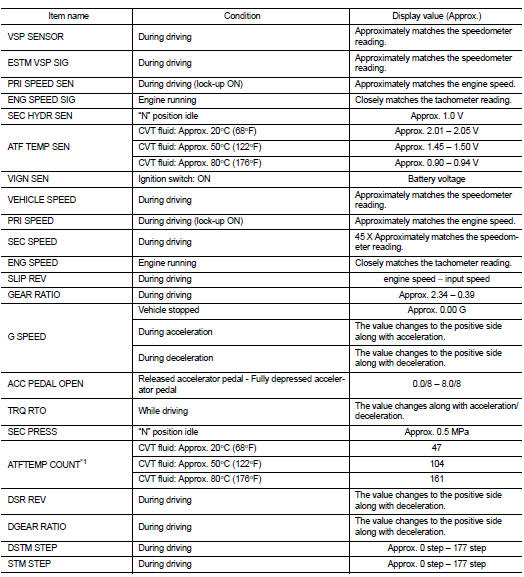

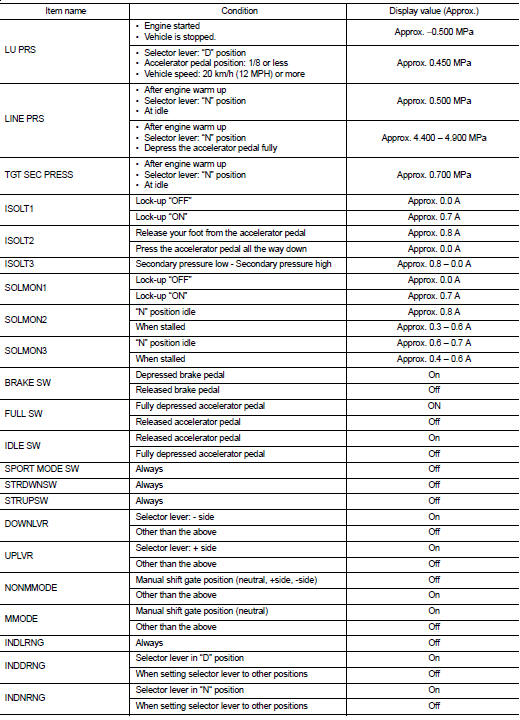

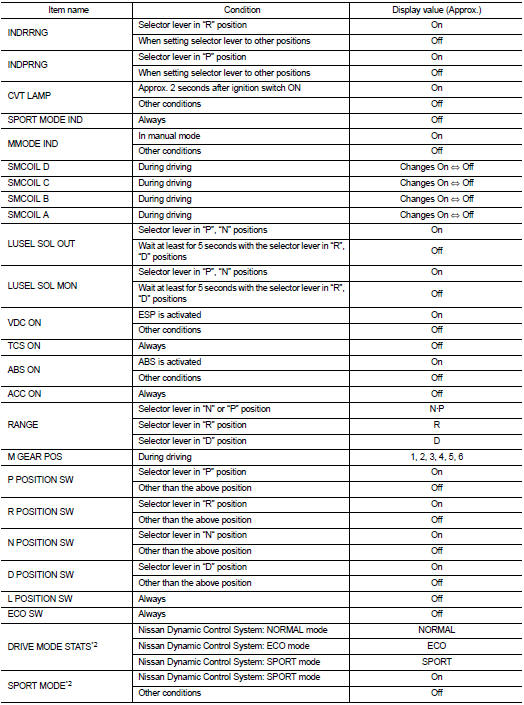

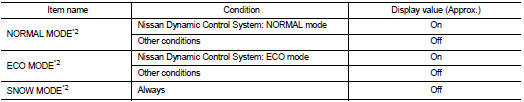

VALUES ON THE DIAGNOSIS TOOL

*1: Means CVT fluid temperature. Convert numerical values for actual fluid temperature °C (°F). Refer to TM-128, "ATFTEMP COUNT Conversion Table".

TERMINAL LAYOUT

PHYSICAL VALUES

*1: This harness is not used.

*2: A circuit tester cannot be used to test this item.

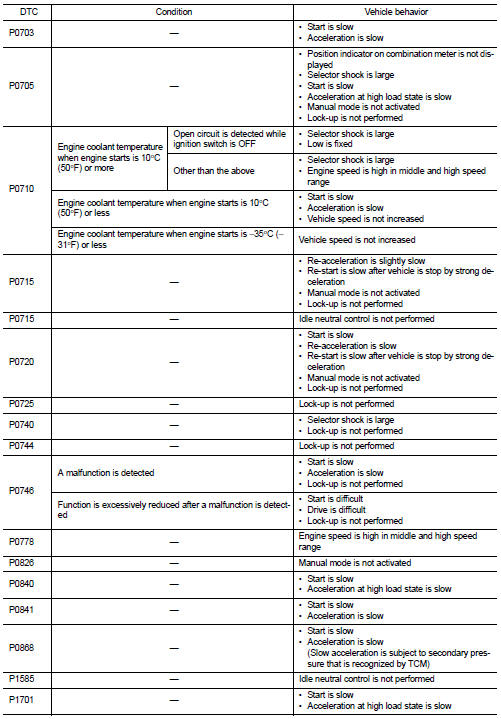

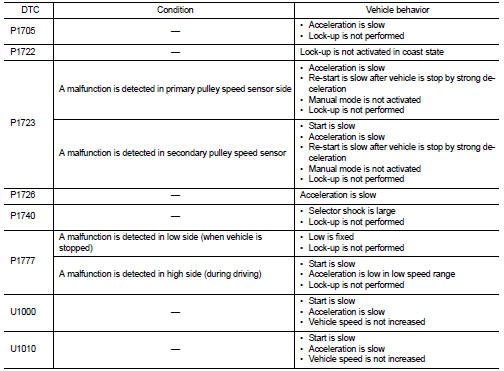

Fail-safe

The TCM has an electrical fail-safe mode. In this mode TCM is operator even if there is an error in a main electronic control input/output signal circuit.

Description

When a malfunction is detected in each sensor, switch, solenoid or others, this

function provides control to

minimize reduction of drivability so that durability of transmission assembly

can be acquired.

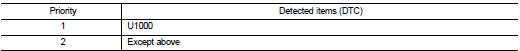

DTC Inspection Priority Chart

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority chart.

NOTE

:

If DTC “U1000” is displayed with other DTCs, first perform the trouble diagnosis

for DTC “U1000”.

Refer to TM-195.

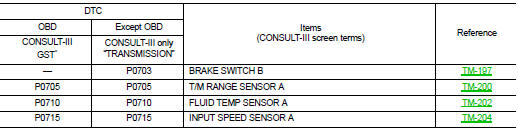

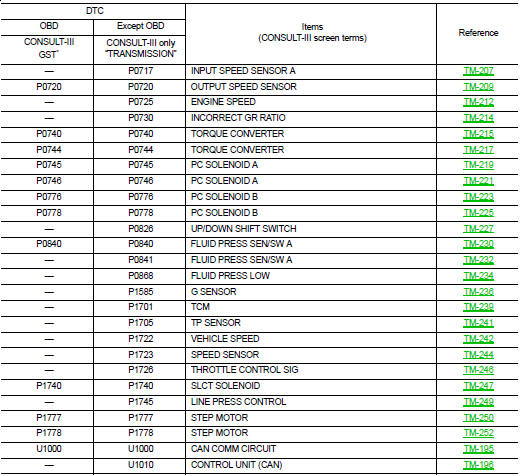

DTC Index

NOTE

:

If DTC “U1000” is displayed with other DTCs, first perform the trouble diagnosis

for DTC “U1000”.

Refer to TM-195.

*: These numbers are prescribed by ISO 15031-5.

Diagnosis system (TCM)

Diagnosis system (TCM)

CONSULT-III Function (TRANSMISSION)

CONSULT-III can display each diagnostic item using the diagnostic test modes

shown below.

FUNCTION

*: “Function Test” can be selected, but do not use it.

...

Wiring diagram

Wiring diagram

...

Other materials:

Drinking alcohol/drugs and driving

WARNING

Never drive under the influence of alcohol or drugs. Alcohol in the bloodstream

reduces coordination, delays reaction time and impairs judgement.

Driving after drinking alcohol increases the likelihood of being involved in

an accident injuring yourself and others.

Additionally, if you ...

Engine compartment

CAUTION

Never use a fuse of a higher or lower amperage rating than that specified

on the fuse box cover. This could damage the electrical system or cause a fire.

If any electrical equipment does not operate, check for an open fuse.

1. Be sure the ignition switch and the headlight switch are t ...

Key out interlock door unlock function does not operate

Diagnosis Procedure

1.CHECK “AUTOMATIC LOCK/UNLOCK SELECT” SETTING IN “WORK SUPPORT”

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “AUTOMATIC LOCK/UNLOCK SELECT” in “WORK SUPPORT” mode.

3. Check “AUTOMATIC LOCK/UNLOCK SELECT” in “WORK SUPPORT”.

Refer to DLK-371, "DOOR LOCK ...