Nissan Juke Service and Repair Manual : Diagnosis and repair workflow

Work Flow

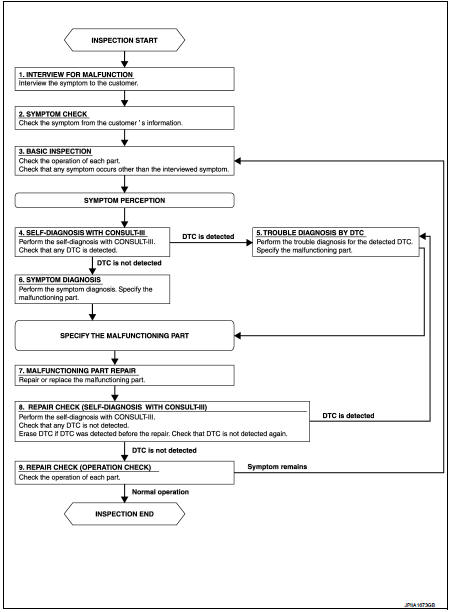

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Interview the symptom to the customer.

>> GO TO 2.

2.SYMPTOM CHECK

Check the symptom from the customer's information.

>> GO TO 3.

3.BASIC INSPECTION Check the operation of each part. Check that any symptom occurs other than the interviewed symptom.

>> GO TO 4.

4.SELF-DIAGNOSIS WITH CONSULT-III

Perform the self-diagnosis with CONSULT-III. Check that any DTC is detected.

Is any DTC detected? YES >> GO TO 5.

NO >> GO TO 6.

5.TROUBLE DIAGNOSIS BY DTC

Perform the trouble diagnosis for the detected DTC. Specify the malfunctioning part.

>> GO TO 6.

6.SYMPTOM DIAGNOSIS

Perform the symptom diagnosis. Specify the malfunctioning part.

>> GO TO 7.

7.MALFUNCTION PART REPAIR

Repair or replace the malfunctioning part.

>> GO TO 8.

8.REPAIR CHECK (SELF-DIAGNOSIS WITH CONSULT-III)

Perform the self-diagnoses with CONSULT-III. Check that any DTC is not detected. Erase DTC if DTC is detected before the repair. Check that DTC is not detected again.

Is any or malfunction result or DTC detected? YES >> If DTC is detected, GO TO 5.

NO >> GO TO 9.

9.REPAIR CHECK (OPERATION CHECK)

Check the operation of each part.

Does it operate normally? YES >> INSPECTION END

NO >> GO TO 3.

Basic inspection

Basic inspection

...

Operation inspection

Operation inspection

Work Procedure

The purpose of the operational check is to check that the individual system

operates normally.

Check condition : Engine running at normal operating temperature.

1.CHECK BLOWER MOTO ...

Other materials:

P0122, P0123 TP SENSOR

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0122 or P0123 is displayed with DTC P0643, first perform the trouble

diagnosis for DTC P0643.

Refer to EC-686, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, alw ...

Shift position indicator circuit

Description

• TCM sends position indicator signals to combination meter by CAN

communication line.

• Manual mode switch position is indicated on shift position indicator

Component Function Check

1.CHECK SHIFT POSITION INDICATOR

CAUTION:

Always drive vehicle at a safe speed.

1. Start engine. ...

P1550 battery current sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following before conducting

the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. ...