Nissan Juke Service and Repair Manual : Diagnosis and repair work flow

Work Flow

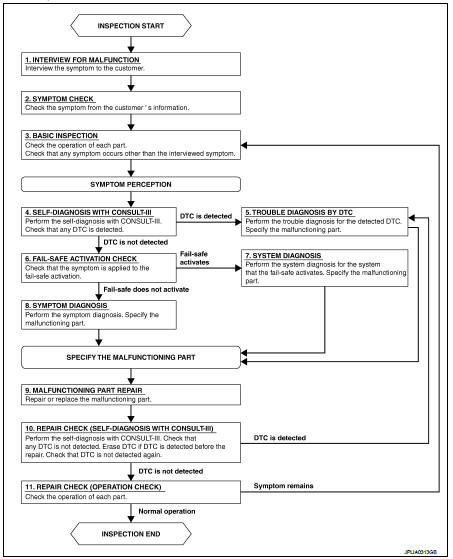

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Interview the symptom to the customer.

>> GO TO 2.

2.SYMPTOM CHECK

Check the symptom from the customer's information.

>> GO TO 3.

3.BASIC INSPECTION Check the operation of each part. Check that any symptom occurs other than the interviewed symptom.

>> GO TO 4.

4.SELF-DIAGNOSIS WITH CONSULT-III

Perform the self-diagnosis with CONSULT-III. Check that any DTC is detected.

Is any DTC detected? YES >> GO TO 5.

NO >> GO TO 6.

5.TROUBLE DIAGNOSIS BY DTC

Perform the trouble diagnosis for the detected DTC. Specify the malfunctioning part.

>> GO TO 9.

6.FAIL-SAFE ACTIVATION CHECK

Check that the symptom is applied to the fail-safe activation.

Does the fail-safe activate? YES >> GO TO 7.

NO >> GO TO 8.

7.SYSTEM DIAGNOSIS

Perform the system diagnosis for the system that the fail-safe activates. Specify the malfunctioning part.

>> GO TO 9.

8.SYMPTOM DIAGNOSIS

Perform the symptom diagnosis. Specify the malfunctioning part.

>> GO TO 9.

9.MALFUNCTION PART REPAIR

Repair or replace the malfunctioning part.

>> GO TO 10.

10.REPAIR CHECK (SELF-DIAGNOSIS WITH CONSULT-III)

Perform the self-diagnosis with CONSULT-III. Check that any DTC is not detected. Erase DTC if DTC is detected before the repair. Check that DTC is not detected again.

Is any DTC detected? YES >> GO TO 5.

NO >> GO TO 11.

11.REPAIR CHECK (OPERATION CHECK)

Check the operation of each part.

Does it operate normally? YES >> INSPECTION END

NO >> GO TO 3.

Basic inspection

Basic inspection

...

Operation inspection

Operation inspection

Work Procedure

The purpose of the operational check is to check that the individual system

operates normally.

Check condition : Engine running at normal operating temperature.

1.CHECK MEMORY FUNC ...

Other materials:

General Precautions

WARNING:

When replacing fuel line parts, be sure to observe the following.

• Put a ???CAUTION: FLAMMABLE??? sign in the workshop.

• Be sure to work in a well ventilated area and furnish workshop with a CO2 fire

extinguisher.

• Never smoke while servicing fuel system. Keep open flames and spa ...

Secondary speed sensor

Exploded View

1. Transaxle assembly

2. Secondary speed sensor

3. O-ring

: Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: Genuine NISSAN CVT Fluid NS-2

Removal and Installation

REMOVAL

1. Remove air cleaner case. Refer to EM-26, "Removal and Installation".

2. ...

System

Engine control system : System Diagram

Engine control system : System Description

ECM performs various controls such as fuel injection control and ignition

timing control.

MULTIPORT FUEL INJECTION SYSTEM

Multiport fuel injection system : System Diagram

Multiport fuel injection system : ...