Nissan Juke Service and Repair Manual : Compressor dose dot operate

Description

SYMPTOM Compressor dose not operate.

Diagnosis Procedure

NOTE

:

• Perform self-diagnosis with CONSULT-III before performing symptom diagnosis.

If any malfunction result or

DTC is detected, perform the corresponding diagnosis.

• Check that refrigerant is enclosed in cooler cycle normally. If the refrigerant amount is shortage from proper amount, perform the inspection of refrigerant leakage 1.CHECK A/C INDICATOR

1. Turn ignition switch ON.

2. Operate blower motor.

3. Check that A/C indicator is turned ON/OFF when operating A/C switch.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 5.

2.CHECK MAGNET CLUTCH OPERATION

Check magnet clutch. Refer to HAC-232, "Component Function Check".

Does it operate normally? YES >> GO TO 3.

NO >> Repair or replace malfunctioning parts.

3.CHECK REFRIGERANT PRESSURE SENSOR

Check refrigerant pressure sensor. Refer to EC-423, "Component Function Check".

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace malfunctioning parts.

4.CHECK BCM OUTPUT SIGNAL

With CONSULT-III

With CONSULT-III

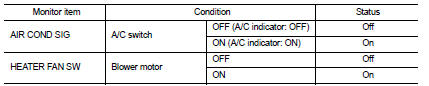

1. Select “DATA MONITOR” mode of “ECM” using CONSULT-III.

2. Select “AIR COND SIG” and “HEATER FAN SW”, and check status under the following conditions.

Is the inspection result normal? YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation" (with Intelligent Key) or PCS-63, "Removal and Installation" (without Intelligent Key).

NO >> Replace BCM. Refer to BCS-93, "Removal and Installation" (with Intelligent Key) or BCS-161, "Removal and Installation" (without Intelligent Key).

5.CHECK A/C SWITCH

Check A/C switch. Refer to HAC-220, "Component Function Check".

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace the malfunctioning parts.

6.CHECK BLOWER FAN ON SIGNAL

Check blower fan ON signal. Refer to HAC-222, "Component Function Check".

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace the malfunctioning parts 7.CHECK THERMO CONTROL AMP.

Check thermo control amp. Refer to HAC-224, "Component Function Check".

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-93, "Removal and Installation" (with Intelligent Key) or BCS-161, "Removal and Installation" (without Intelligent Key).

NO >> Repair or replace the malfunctioning parts

Insufficient heating

Insufficient heating

Description

Symptom

• Insufficient heating

• No warm air comes out. (Air flow volume is normal.)

Diagnosis Procedure

NOTE:

Perform self-diagnosis with CONSULT-III before performing symptom diagn ...

Other materials:

P1611 ID discord, IMMU-ECM

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check DTC in “Self Diagnostic Result” mode of “ENGINE” using CONSULT-III.

Is DTC detected?

YES >> Go to SEC-53, "Diagnosis Procedure".

NO >> ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT

PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...

PTC heater

Component Function Check

1.CHECK PTC HEATER OPERATION

1. Start the engine.

2. Operate fan control dial.

3. Operate temperature control dial to full hot position.

4. Check for warm air at discharge air outlet.

NOTE:

• Engine must be cold.

• Battery must be charged.

Is the inspection resu ...