Nissan Juke Service and Repair Manual : Coil spring

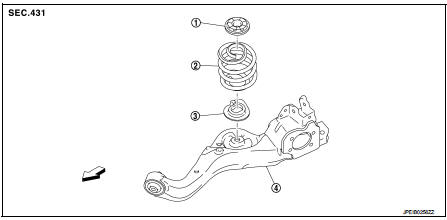

Exploded View

1. Upper rubber seat

2. Coil spring

3. Lower rubber seat

4. Suspension arm

: Vehicle front

: Vehicle front

Removal and Installation

REMOVAL

1. Remove tires. Refer to WT-7, "Removal and Installation".

2. Remove wheel sensor and sensor harness. Refer to BRC-86, "REAR WHEEL SENSOR : Removal and Installation" (Without ESP), BRC-227, "REAR WHEEL SENSOR : Removal and Installation" (With ESP).

3. Set jack under suspension arm.

CAUTION:

• Never damage the suspension arm with a jack.

• Check the stable condition when using a jack.

4. Separate rear shock absorber lower side form suspension arm. Refer to RSU-8, "Removal and Installation".

5. Separate upper link from suspension arm.

6. Slowly lower jack, then remove upper rubber seat, coil spring and lower rubber seat from suspension arm.

CAUTION:

Operate while checking that jack supporting status is stable.

7. Perform inspection after removal. Refer to RSU-27, "Inspection" INSTALLATION

Note the following, and install in the reverse order of removal.

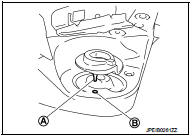

• Install the lower rubber seat a projection (A) is attached as suspension arm mounting hole (B).

• Match up lower rubber seat indentions and suspension arm grooves and attach.

• Perform inspection after installation. Refer to RSU-27, "Inspection".

Inspection

INSPECTION AFTER REMOVAL

Check lubber seat and coil spring for deformation, crack, and damage. Replace it if necessary.

INSPECTION AFTER INSTALLATION

1. Check wheel sensor harness for proper connection. Refer toBRC-85, "REAR WHEEL SENSOR : Exploded View" (Without ESP), BRC-225, "REAR WHEEL SENSOR : Exploded View" (With ESP).

2. Check wheel alignment. Refer to RSU-20, "Inspection".

Rear shock absorber

Rear shock absorber

Exploded View

1. Suspension arm

2. Shock absorber

3. Bound bumper

4. Bound bumper cover

5. Washer

6. Bushing

7. Distance tube

8. Piston rod lock nut

9. Cap

: Vehicle front

: Always r ...

Suspension arm

Suspension arm

Exploded View

1. Rear suspension member

2. Adjusting bolt

3. Upper link

4. Eccentric disk

5. Lower link

6. Suspension arm bracket

7. Suspension arm

: Vehicle front

: Always replace afte ...

Other materials:

P position warning does not operate

Diagnosis Procedure

1.CHECK DTC WITH BCM, TCM AND COMBINATION METER

Check that DTC is not detected with BCM, TCM and combination meter.

Is the inspection result normal?

YES >> GO TO 2.

NO-1 >> Refer to BCS-67, "DTC Index". (BCM)

NO-2 >> Refer to TM-171, "DT ...

P1739 1GR incorrect ratio

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

• Be sure to perform “TM-442, "Diagnosis Procedure"” and then perform “DTC

CONFIRMATION PROCEDURE”.

• Never perform "DTC CONFIRMATION PROCEDURE" before the repairs. Doing so may

result in a secondary

ma ...

P0001 fuel pump

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0001 is displayed with DTC P0560 or P0657, first perform trouble

diagnosis for DTC P0560 or P0657.

Refer to EC-963, "DTC Logic" (DTC P0560) or EC-976, "DTC Logic" (DTC P0657).

Diagnosis Procedure

1.CHECK HIGH PRESSURE SUPPLY ...