Nissan Juke Service and Repair Manual : Rear shock absorber

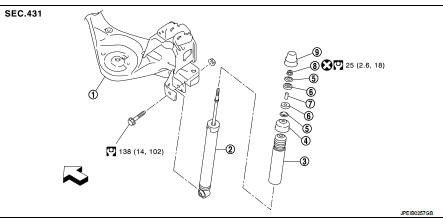

Exploded View

1. Suspension arm

2. Shock absorber

3. Bound bumper

4. Bound bumper cover

5. Washer

6. Bushing

7. Distance tube

8. Piston rod lock nut

9. Cap

: Vehicle front

: Vehicle front

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Remove tires. Refer to WT-7, "Removal and Installation".

2. Set suitable jack under suspension arm.

CAUTION:

• Never damage the suspension arm with a jack.

• Check the stable condition when using a jack.

3. Remove shock absorber mounting bolt and nut (lower side).

4. Remove shock absorber mask. Refer to INT-29, "Exploded View".

5. Remove cap.

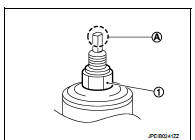

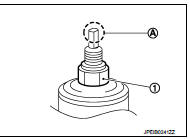

6. Remove piston rod lock nut (1), and then remove washer and bushing.

NOTE

:

To loosen piston rod lock nut, fix the tip (A) of the piston rod.

7. Remove shock absorber assembly.

8. Remove bushing, distance tube, bound bumper cover, and bound bumper from shock absorber.

9. Perform inspection after removal. Refer to RSU-24, "Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

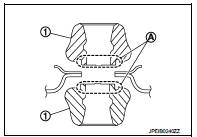

• To install bushings (1), securely insert protrusion (A) into the hole on the vehicle body side.

• Install washer (1) in the direction shown in the figure.

: Bushing side

• Perform final tightening of bolts and nuts at the shock absorber lower side (rubber bussing), under unladen conditions with tires on level ground.

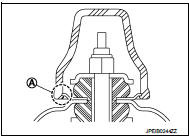

• Hold a head (A) of shock absorber piston rod not to have it rotate, then tighten the piston rod lock nut (1) to the specified torque.

CAUTION:

Never reuse piston rod lock nut.

• When installing the cap, securely engage the cap groove (A) with the flange on the vehicle side.

• Perform inspection after installation. Refer to RSU-24, "Inspection".

• After replacing the shock absorber, always follow the disposal procedure to discard the shock absorber. Refer to RSU-24, "Inspection".

Inspection

INSPECTION AFTER REMOVAL

Shock Absorber

Check the following items, and replace the part if necessary.

• Shock absorber for deformation, cracks, and other damage.

• Piston rod for damage, uneven wear, and distortion.

• Oil leakage

Bound Bumper, Bushing Check for cracks and damage. Replace it if necessary.

Washer, Bound Bumper Cover, Distance Tube • Check for cracks and damage. Replace it if necessary.

INSPECTION AFTER INSTALLATION

Check wheel alignment. Refer to RSU-20, "Inspection".

Disposal

1. Set shock absorber horizontally to the ground with the piston rod fully extracted.

2. Drill 2 – 3 mm (0.08 – 0.12 in) hole at the position (

) from top

) from top

as shown in the figure to release gas gradually.

CAUTION:

• Wear eye protection (safety glass).

• Wear gloves.

• Be careful with metal chips or oil blown out by the compressed gas.

NOTE:

• Drill vertically in this direction (

).

).

• Directly to the outer tube avoiding brackets.

• The gas is clear, colorless, odorless, and harmless.

A : 20 – 30 mm (0.79 – 1.18 in)

3. Position the drilled hole downward and drain oil by moving the piston rod several times.

CAUTION:

Dispose of drained oil according to the law and local regulations.

Coil spring

Coil spring

Exploded View

1. Upper rubber seat

2. Coil spring

3. Lower rubber seat

4. Suspension arm

: Vehicle front

Removal and Installation

REMOVAL

1. Remove tires. Refer to WT-7, "Removal and ...

Other materials:

B1074, B1075, B1076, B1077, B1078, B1079 diagnosis sensor unit

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

Diagnosis system (ECM)

Diagnosis description : 1st Trip Detection Logic and Two Trip Detection

Logic

When a malfunction is detected for the first time, 1st trip DTC and 1st trip

Freeze Frame data are stored in the

ECM memory. The MI will not illuminate at this stage. <1st trip>

If the same malfunction is dete ...

Rear washer nozzle and tube

Hydraulic Layout

1. Rear washer nozzle

2. Plug

3. Rear washer tube

4. Joint

5. Second washer tube

6. Back door seal rubber

7. Front washer tube

: Clip

: Pawl

Removal and Installation

REMOVAL

1. Remove luggage side upper finisher RH. Refer to INT-32, "LUGGAGE SIDE

UPPER FINIS ...