Nissan Juke Service and Repair Manual : C1140 actuator relay system

DTC Logic

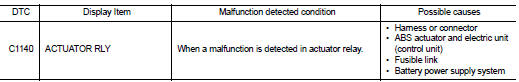

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT-III.

With CONSULT-III.

1. Turn the ignition switch OFF to ON.

2. Perform self-diagnosis for “ABS”.

Is DTC “C1140” detected? YES >> Proceed to BRC-60, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Check ABS actuator and electric unit (control unit) harness connector for disconnection or looseness.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace error-detected parts, securely lock the connector, and GO TO 2.

2.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis for “ABS” again.

Is DTC “C1140” detected? YES >> GO TO 3.

NO >> INSPECTION END

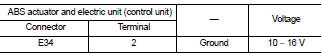

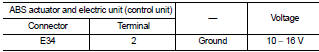

3.CHECK ACTUATOR RELAY POWER SUPPLY

1. Turn the ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) harness connector.

3. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

4. Turn the ignition switch ON.

CAUTION:

Never start engine.

5. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK ACTUATOR RELAY POWER SUPPLY CIRCUIT

1. Turn the ignition switch OFF.

2. Check 40 A fusible link (F).

3. Check continuity and short circuit between ABS actuator and electric unit (control unit) harness connector terminal (2) and 40 A fusible link (F).

Is the inspection result normal? YES >> Perform trouble diagnosis for battery power supply. Refer to PG-10, "Wiring Diagram - BATTERY POWER SUPPLY -".

NO >> Repair or replace error-detected parts.

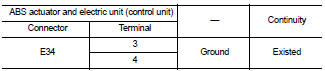

5.CHECK ACTUATOR RELAY GROUND CIRCUIT

1. Turn the ignition switch OFF.

2. Check continuity between ABS actuator and electric unit (control unit) harness connector and the ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.CHECK TERMINAL

Check ABS actuator and electric unit (control unit) pin terminals for damage or loose connection with harness connector.

Is the inspection result normal? YES >> Replace ABS actuator and electric unit (control unit). Refer to BRC-90, "Removal and Installation".

NO >> Repair or replace error-detected parts.

C1121, C1123, C1125, C1127 ABS out valve system

C1121, C1123, C1125, C1127 ABS out valve system

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

U1000 can comm circuit

U1000 can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellen ...

Other materials:

Primary speed sensor

Exploded View

1. Transaxle assembly

2. O-ring

3. Primary speed sensor

: Always replace after every

disassembly.

: N m (kg-m, in-lb)

: Genuine NISSAN CVT Fluid NS-2

Removal and Installation

REMOVAL

1. Remove the battery. Refer to PG-124, "Removal and Installation".

2. Remove ...

Power generation voltage variable control system operation

inspection

Inspection Procedure

CAUTION:

When performing this inspection, always use a charged battery that has completed

the battery inspection.

(When the charging rate of the battery is low, the response speed of the voltage

change will

become slow. This can cause an incorrect inspection.)

1.CHECK ...

Speed limiter

Speed limiter : System Diagram

Speed limiter : System Description

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM through CAN communication line

BASIC SPEED LIMITER SYSTEM

• Speed limiter is a system that enables to restrict the vehicle speed within

the set speed that is sele ...