Nissan Juke Service and Repair Manual : Body construction

Body Construction (RHD Models)

1. Outer side body

2. Outer front pillar reinforcement

3. Upper inner front pillar

4. Lower dash

5. Hoodledge reinforcement

6. Lower front pillar hinge brace

7. Weld nut

8. Side dash

9. Upper hinge plate

10. Lower hinge plate

11. Inner front pillar reinforcement

12. Inner front sill reinforcement

13. Inner sill

14. Front floor reinforcement

15. Front floor

16. Front outrigger

17. Outer sill reinforcement

18. Plate nut

19. Inner center pillar

20. Center pillar reinforcement

21. Center pillar hinge brace

22. Center sill reinforcement

23. Inner sill extension

24. Inner rear wheelhouse

25. Outer rear wheelhouse

26. Rear roof rail brace

27. Inner rear pillar reinforcement

28. Rear fender extension

29. Inner rear pillar

30. Inner rear wheelhouse reinforcement

Body Construction (LHD Models)

1. Outer side body

2. Outer front pillar reinforcement

3. Upper inner front pillar

4. Lower dash

5. Hoodledge reinforcement

6. Lower front pillar hinge brace

7. Weld nut

8. Side dash

9. Upper hinge plate

10. Lower hinge plate

11. Inner front pillar reinforcement

12. Inner front sill reinforcement

13. Inner sill

14. Front floor reinforcement

15. Front floor

16. Front outrigger

17. Outer sill reinforcement

18. Plate nut

19. Inner center pillar

20. Center pillar reinforcement

21. Center pillar hinge brace

22. Center sill reinforcement

23. Inner sill extension

24. Inner rear wheelhouse

25. Outer rear wheelhouse

26. Rear roof rail brace

27. Inner rear pillar reinforcement

28. Rear fender extension

29. Inner rear pillar

30. Inner rear wheelhouse reinforcement

31. Upper inner front pillar reinforcement

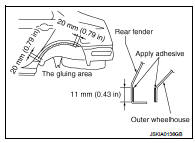

Rear Fender Hemming Process

1. A wheel arch is to be installed and hemmed over the left and right outer wheel houses.

2. In order to hem the wheel arch, it is necessary to repair any damaged or defaced parts around outer wheel house.

CAUTION:

Ensure that the area that is to be glued around the outer wheelhouse is

undamaged or defaced.

PROCEDURE OF THE HEMMING PROCESS

• Peel off old bonding material on the surface of the outer wheelhouse and clean thoroughly.

• Peel off a primer coat in the specified area where new adhesive is to be applied on rear fender (the replacing part).

• Apply new adhesive to both specified areas of the outer wheelhouse and rear fender.

<Adhesive> 3M™ Automix™ Panel Bonding Adhesive 08115 or equivalent

• Attach rear fender to the body of the car, and weld the required part except the hemming part.

• Bend the welded part starting from the center of the wheel arch

gradually with a hammer and a dolly. (Also hem the end of the

flange.)

• Hemming with a hammer is conducted to an approximate angle of

80 degrees.

• Starting from the center, hem the wheel arch gradually, using slight back and forth motion with a hemming tool.

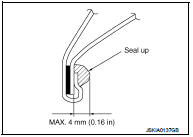

• Seal up the area around the hemmed end of the flange.

Corrosion protection

Corrosion protection

Description

To provide improved corrosion prevention, the following anti-corrosive

measures have been implemented in

NISSAN production plants. When repairing or replacing body panels, it is

nece ...

Replacement operations

Replacement operations

Description

• This section is prepared for technicians who have attained a high level of

skill and experience in repairing

collision-damaged vehicles and also use modern service tools and equipmen ...

Other materials:

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...

Exterior lighting system symptoms

Without daytime running light system

WITHOUT DAYTIME RUNNING LIGHT SYSTEM : Symptom Table

CAUTION:

Perform the self-diagnosis with CONSULT-III before the symptom diagnosis.

Perform the trouble diagnosis

if any DTC is detected.

With daytime running light system

WITH DAYTIME RUNNING LIGHT ...

Fillet molding

Exploded View

1. Grommet

2. Clip

3. Clip

4. Front fillet molding

5. Rear fillet molding

: Pawl

: Do not reuse

Front fillet molding

FRONT FILLET MOLDING : Removal and Installation

REMOVAL

1. Remove front fillet molding fixing clips.

2. Remove front fillet molding front side fixing pa ...