Nissan Juke Service and Repair Manual : B1180 lap Pre-tensioner RH

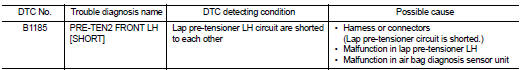

DTC Logic

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp status. Refer to SRC-12, "On Board Diagnosis Function".

NOTE

:

SRS does not enter diagnosis mode if no malfunction is detected in user mode.

Is malfunctioning part detected? YES >> Refer to SRC-133, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

WARNING:

• Before servicing, turn ignition switch OFF, disconnect battery negative

terminal and wait at least 3

minutes. (To discharge backup capacitor.)

• Never use unspecified tester or other measuring device.

1.CHECK HARNESS CONNECTOR

Check the harness connector.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace harness connector.

2.CHECK WIRING HARNESS

Check the wiring harness externals.

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace wiring harness.

3.REPLACE LAP PRE-TENSIONER LH

1. Replace lap pre-tensioner LH. Refer to SR-33, "Removal and Installation".

2. Perform DTC confirmation procedure. Refer to SRC-133, "DTC Logic".

Is DTC detected? YES >> GO TO 4.

NO >> INSPECTION END

4.REPLACE AIR BAG DIAGNOSIS SENSOR UNIT

1. Replace air bag diagnosis sensor unit. Refer to SR-30, "Removal and Installation".

2. Perform DTC confirmation procedure. Refer to SRC-133, "DTC Logic".

Is DTC detected? YES >> GO TO 1.

NO >> INSPECTION END

B1179 lap Pre-tensioner RH

B1179 lap Pre-tensioner RH

DTC Logic

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

With ...

B1182 lap Pre-tensioner LH

B1182 lap Pre-tensioner LH

DTC Logic

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

With ...

Other materials:

Disposal of air bag module

Driver air bag module : Deployment

CHECKING DEPLOYMENT TOOL

Connecting to Battery

CAUTION:

The battery must show voltage of 9.6 V or more.

Remove the battery from the vehicle and place it on dry wood blocks

approximately 5.0 m (16.4 ft) away from the vehicle.

• Wait 3 minutes after the vehi ...

Ecu diagnosis informatioN

TCM

Reference Value

VALUES ON THE DIAGNOSIS TOOL

*1: Means CVT fluid temperature. Convert numerical values for actual fluid

temperature °C (°F). Refer to TM-128, "ATFTEMP COUNT

Conversion Table".

TERMINAL LAYOUT

PHYSICAL VALUES

*1: This harness is not used.

*2: ...

Push-button ignition switch position indicator does not illuminate

Description

• Before performing the diagnosis in the following table, check “Work Flow”.

Refer to PCS-88, "Work Flow".

• Check that vehicle is under the condition shown in “Conditions of vehicle”

before starting diagnosis, and

check each symptom.

Conditions of Vehicle (Operating ...