Nissan Juke Service and Repair Manual : Additional service when replacing transaxle assembly

Description

Perform the following work after the transaxle assembly is replaced.

CHECK LOADING OF CALIBRATION DATA

• The TCM acquires calibration data (individual characteristic value) of each solenoid that is stored in the ROM assembly (in the control valve). This enables the TCM to perform accurate control. After the TCM is replaced, check that the TCM has correctly loaded the calibration data.

G sensor calibration

• TCM stores calibration data (inherent characteristic value) of G sensor to

provide accurate control. Therefore,

it is required to perform calibration of G sensor after the following work is

performed.

Idle neutral control

• TCM corrects an individual difference in clutch clearance of the transaxle

assembly by performing the idle

neutral control learning and enables accurate idle neutral control.

• Therefore, it is required to perform idle neutral control learning after replacement or TCM.

CAUTION:

• When replacing TCM and transaxle assembly as a set, replace transaxle assembly

first and then

replace TCM.

• If the TCM is replaced in advance, perform the following items.

1. ADDITIONAL SERVICE WHEN REPLACING CONTROL VALVE OR TRANSAXLE ASSEMBLY 2. CALIBRATION OF G SENSOR 3. IDLE NEUTRAL CONTROL LEARNING

Procedure

CAUTION:

Immediately after TCM is replaced or after control valve or transaxle assembly

is replaced (after TCM

initialization is complete), self-diagnosis result of “P1701” may be displayed.

In this case, erase selfdiagnosis

result using CONSULT-III. After erasing self-diagnosis result, perform DTC P1701

reproduction

procedure and check that malfunction is not detected. Refer to TM-239, "DTC

Logic".

1.PREPARATION BEFORE WORK

With CONSULT-III

With CONSULT-III

1. Start the engine.

CAUTION:

Never drive the vehicle.

2. Select “Data monitor” in “TRANSMISSION”.

3. Select “ATFTEMP COUNT”.

Is “ATFTEMP COUNT” 47 [equivalent to 20°C (68°F)] or more? YES >> GO TO 2.

NO >> 1. Warm up the transaxle assembly until “ATFTEMP COUNT” reaches “47” [equivalent to 20°C (68°F)] or more.

2. GO TO 2.

2.PERFORM TCM INITIALIZATION

With CONSULT-III

1. Turn ignition switch OFF.

2. Turn ignition switch ON.

CAUTION:

Never start the engine.

3. Select “Self Diagnostic Results” in “TRANSMISSION”.

4. Shift selector lever to “R” position.

5. Depress slightly the accelerator pedal (Pedal angle: 2.0/8) while depressing the brake pedal.

6. Select “Erase” with step 5.

7. Release brake pedal and accelerator pedal.

8. Turn ignition switch OFF while keeping the selector lever in “R” position.

9. Wait approximately 10 seconds.

10. Turn ignition switch ON while keeping the selector lever in “R” position.

11. Select “Special function” in “TRANSMISSION”.

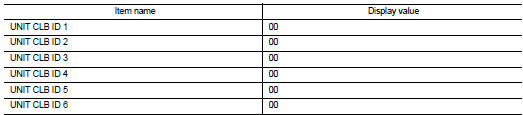

12. Select “CALIB DATA”.

13. Check that “CALIB DATA” value is as shown as in the following table.

Is “CALIB DATA” value it? YES >> GO TO 3.

NO >> GO TO 1.

3.CHECK AFTER WORK

1. Shift selector lever to “P” position.

2. Check that “P” is displayed on shift position indicator on combination meter.

NOTE

:

It indicates approximately 1 or 2 seconds after shifting the selector lever to

“P” position.

Does shift position indicator display “P”? YES >> GO TO 5.

NO >> GO TO 4.

4.DETECTION OF MALFUNCTION ITEMS

Check the following items: • Harness between the TCM and the ROM assembly inside the transaxle assembly is open or shorted.

• Disconnected, loose, bent, collapsed, or otherwise abnormal connector housing

terminals

• Power supply and ground of TCM. (Refer to TM-239, "Diagnosis Procedure".)

Is the inspection result normal?

YES >> GO TO 1.

NO >> Repair or replace the malfunctioning parts.

5.PERFORM G SENSOR CALIBRATION

Refer to TM-182, "Procedure".

>> GO TO 6.

6.PERFORM IDLE NEUTRAL CONTROL LEARNING

Refer to TM-183, "Description".

>> WORK END

Additional service when replacing TCM

Additional service when replacing TCM

Description

Always perform the following items when the TCM is replaced.

CHECK LOADING OF CALIBRATION DATA

• The TCM acquires calibration data (individual characteristic value) of each

solenoid t ...

Calibration of decel G sensor

Calibration of decel G sensor

Description

TCM stores calibration data (inherent characteristic value) of G sensor to

provide accurate control. Therefore,

it is required to perform calibration of G sensor after the following wo ...

Other materials:

Engine bucking

Description

CHART 9: ENGINE BUCKING

Diagnosis Procedure

1.CHECK ECM POWER SUPPLY AND GROUND CIRCUIT

Check ECM power supply and ground circuit. Refer to EC-885, "Diagnosis

Procedure".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace harness o ...

Temperature A, B and C

The temperature grades A (the highest), B, and C, representing the tire’s resistance

to the generation of heat and its ability to dissipate heat when tested under controlled

conditions on a specified indoor laboratory test wheel. Sustained high temperature

can cause the material of the tire to ...

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Always use CONS ...