Nissan Juke Service and Repair Manual : Encoder circuit

Component Function Check

1.CHECK ENCODER OPERATION

Check that front driver side door glass perform AUTO UP/DOWN operation normally when power window main switch is operated.

Is the inspection result normal? YES >> INSPECTION END

NO >> Refer to PWC-30, "Diagnosis Procedure".

Diagnosis Procedure

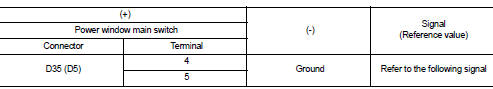

1.CHECK ENCODER PULSE SIGNAL

1. Turn ignition switch ON.

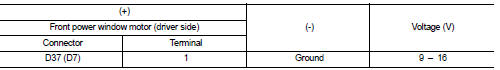

2. Check signal between power window main switch harness connector and ground with oscilloscope.

(): RHD models

Is the inspection result normal? YES >> Replace power window main switch.

NO >> GO TO 2.

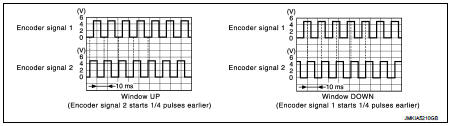

2.CHECK ENCODER SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect power window main switch connector and front power window motor (driver side) connector.

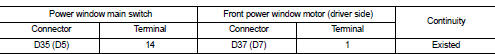

3. Check continuity between power window main switch harness connector and front power window motor (driver side) harness connector.

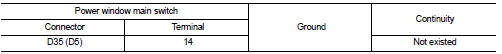

4. Check continuity between power window main switch harness connector and ground.

(): RHD models Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK ENCODER POWER SUPPLY

1. Connect power window main switch connector.

2. Turn ignition switch ON.

3. Check voltage between front power window motor (driver side) harness connector and ground.

(): RHD models Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK ENCODER POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect power window main switch connector.

3. Check continuity between power window main switch harness connector and front power window motor (driver side) harness connector.

4. Check continuity between power window main switch harness connector and ground.

(): RHD models Is the inspection result normal? YES >> Replace power window main switch.

NO >> Repair or replace harness.

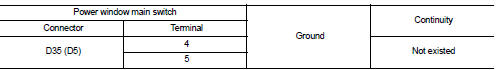

5.CHECK ENCODER GROUND CIRCUIT 1

1. Turn ignition switch OFF.

2. Disconnect power window main switch connector.

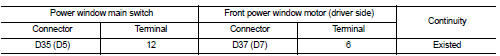

3. Check continuity between power window main switch harness connector and front power window motor (driver side) harness connector.

4. Check continuity between power window main switch harness connector and ground.

(): RHD models

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness.

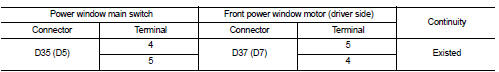

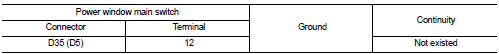

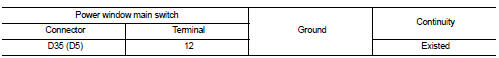

6.CHECK ENCODER GROUND CIRCUIT 2

1. Connect power window main switch connector.

2. Check continuity between power window main switch harness connector and ground.

(): RHD models

Is the inspection result normal? YES >> Replace front power window motor (driver side).

NO >> Replace power window main switch.

Power window motor

Power window motor

DRIVER SIDE

DRIVER SIDE : Component Function Check

1. CHECK FRONT POWER WINDOW MOTOR (DRIVER SIDE) OPERATION

Check front power window motor (driver side) operation with power window main

switch.

...

Other materials:

B2013 steering lock unit

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Lock the steering.

NOTE:

3. Press the push-button ignition switch.

4. Check DTC in “Self Diagnostic Result” mode of “BCM” using CONSULT-III.

Is DTC detected?

YES >> Go to SEC-69, & ...

System

4WD system : System Diagram

INPUT/OUTPUT SIGNAL

It transmits/receives each signal from the following 4WD control module via

CAN communication line.

4WD system : System Description

• 4WD mode is selectable among 2WD, 4WD-V, and 4WD by operating the 4WD mode

switch.

• When judging drivi ...

Water outlet

Exploded View

1. Heater pipe bracket

2. Radiator cap

3. Water outlet adaptor

4. Clamp

5. Water outlet hose

6. Clamp

7. Heater hose

8. Clamp

9. Water outlet

10. Clamp

11. Heater hose

12. Heater hose

13. Clamp

14. Heater hose

15. Clamp

16. Engine coolant temperature sensor ...