Nissan Juke Service and Repair Manual : System

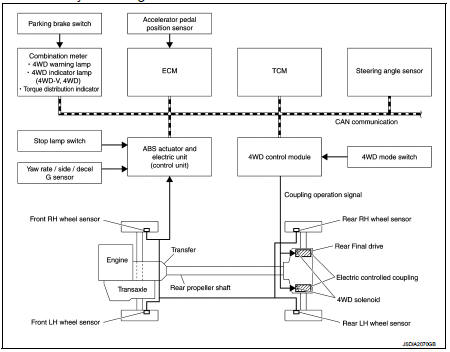

4WD system : System Diagram

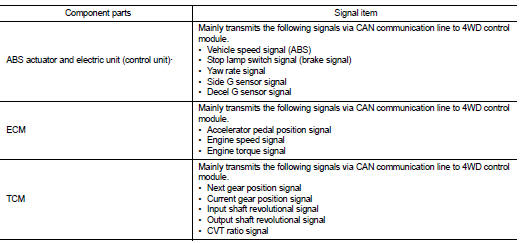

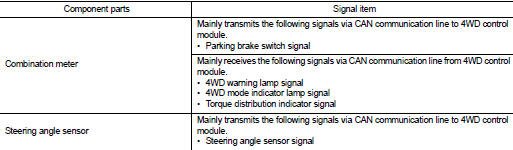

INPUT/OUTPUT SIGNAL

It transmits/receives each signal from the following 4WD control module via CAN communication line.

4WD system : System Description

• 4WD mode is selectable among 2WD, 4WD-V, and 4WD by operating the 4WD mode switch.

• When judging driving conditions and road surface conditions based on signals transmitted from each sensor and switch, the 4WD system automatically controls torque distribution of front and rear wheels and both rear wheels, depending on the situation.

• In accordance with fail-safe function, when system is malfunctioning, 4WD control stops, and the system becomes rear wheel drive. Refer to DLN-19, "4WD SYSTEM : Fail-safe".

• When a high load status continues for electric controlled coupling, 4WD control temporarily becomes rear wheel drive, according to protection function. Refer to DLN-21, "4WD SYSTEM : Protection Function".

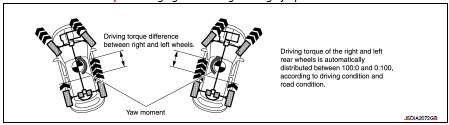

4WD system : Torque Split Control

2WD mode

• Vehicle is in front-wheel drive.

4WD-V mode

Normal Control

• Pressing force of multiple disc clutch is controlled by electric control.

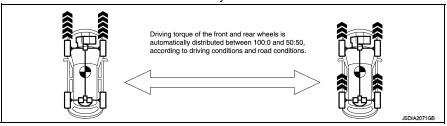

Driving torque distribution of front and

rear wheels changes automatically between approximately 100 : 0 (Front wheel

drive) and 50 : 50 (4WD) to

have an optimized torque distribution adapted to road condition change.

• When spin occurs on front wheel, distribute optimum torque to rear wheel and keep stable driving.

• On roads which do not require 4WD, it contributes to improved fuel economy by driving in conditions close to front-wheel drive and it results in better fuel efficiency.

Cornering Control

• Torque between both rear wheels is automatically changed between 100 : 0 and 0

: 100 for distributing optimum

torque that depends on the driving conditions and road surface conditions.

• Producing a difference between both rear wheels enables sporty and smooth handling.

• The vehicle cornering status is judged according to information from each sensor, and the optimum torque is distributed to rear wheels for preventing tight cornering/braking symptom.

4WD mode

• The 4WD mode controls torque for obtaining suitable torque for driving on

slippery roads (e.g. snow-covered

roads) and provides more stable driving, compared to 4WD-V.

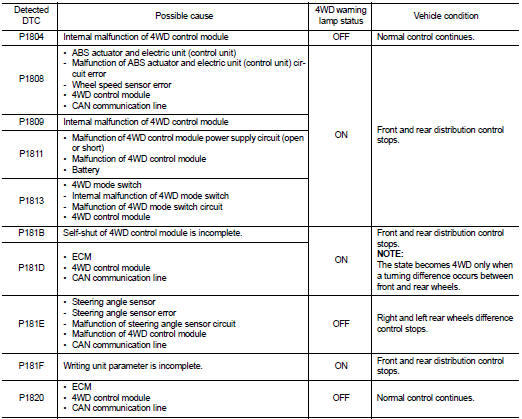

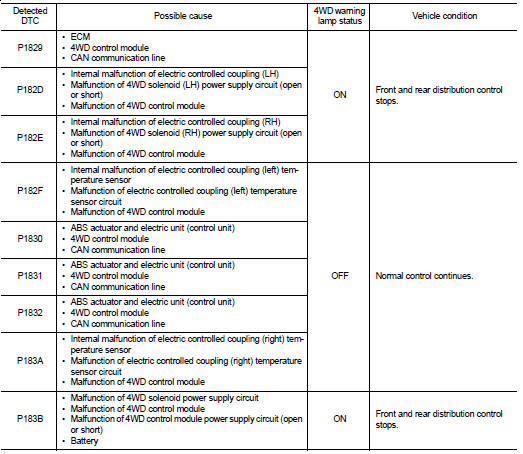

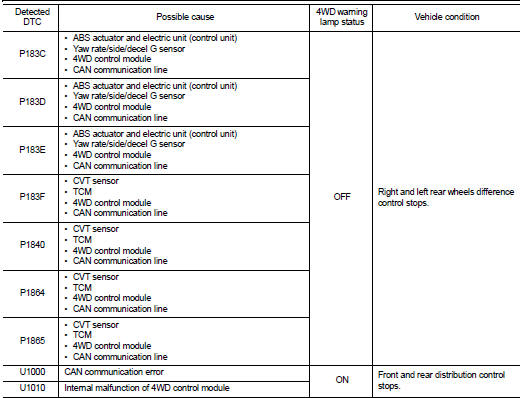

4WD system : Fail-safe

When a system malfunction occurs, the 4WD warning lamp turns ON and the 4WD control becomes 2WD state.

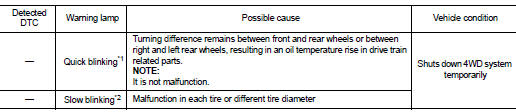

4WD system : Protection Function

4WD system activates its protection function (shuts down 4WD system temporarily) if 4WD system detects high load continuously, the front wheel tire size differs from the rear tire size or the rear RH wheel tire size differs from the rear LH tire size. (4WD system is automatically restored if 4WD system no longer detects any overload or the tire size difference is eliminated.)

*1: 2 times/second (blinking for approximately 1 minute and then turned

OFF)

*2: 1 time/2 seconds (continuing to blink until ignition switch is turned OFF)

NOTE

:

• If the warning lamp blinks slowly during driving but remains OFF after the

engine is restarted, the system is

normal. If it again blinks slowly after driving for some time, vehicle must be

inspected.

• When there is a difference of revolution speed between the front and rear wheel the shift occasionally changes to direct 4-wheel driving conditions automatically. This is not a malfunction.

Structure and operation

Structure and operation

Sectional View

1. Transfer cover

2. Ring gear shaft

3. Companion flange

4. Drive pinion

5. Ring gear

6. Transfer case

Operation Principle

POWER TRANSFER DIAGRAM

1. Engine

2. Transax ...

Diagnosis system (4WD control module)

Diagnosis system (4WD control module)

CONSULT-III Function

APPLICATION ITEMS

CONSULT-III can display each diagnostic item using the diagnostic test modes

as follows.

*: The following diagnosis information is erased by erasing.

• ...

Other materials:

Hazard warning flasher switch

Push the switch on to warn other drivers when you must stop or park under emergency

conditions.

All turn signal lights will flash.

WARNING

• If stopping for an emergency, be sure to move the vehicle well off

the road.

• Do not use the hazard warning flashers while moving on the ...

Symptom diagnosis

Squeak and rattle trouble diagnoses

Work Flow

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist

when the noise occurs. Use the Diagnostic

Worksheet during the interview to document the facts and conditions when the

noise occurs and any of

the cu ...

Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Interview the symptom to the customer.

>> GO TO 2.

2.SYMPTOM CHECK

Check the symptom from the customer's information.

>> GO TO 3.

3.BASIC INSPECTION

Check the operation o ...