Nissan Juke Service and Repair Manual : Unit removal and installation

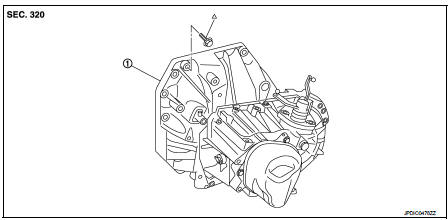

Transaxle assembly

Exploded View

1. Transaxle assembly

: Refer to "INSTALLATION" in

: Refer to "INSTALLATION" in

TM-30, "Removal and Installation" for the locations and tightening torque.

Removal and Installation

CAUTION:

Never reuse CSC (Concentric Slave Cylinder). Because CSC slides back to the

original position every

time when removing transaxle assembly. At this timing, dust on the sliding parts

may damage a seal of

CSC and may cause clutch fluid leakage. Refer to CL-27, "Removal and

Installation".

REMOVAL

1. Disconnect battery cable from negative terminal. Refer to PG-124, "Removal and Installation".

2. Shift the shifter lever to the neutral position.

3. Remove battery. Refer to PG-124, "Removal and Installation".

4. Remove air cleaner case. Refer to EM-161, "Removal and Installation".

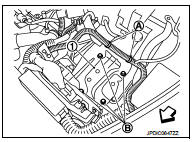

5. Remove bracket (1), as per the following procedure.

: Vehicle front

: Vehicle front

a. Disconnect clips (A) from bracket.

b. Remove bolts (B) from bracket.

c. Remove bracket.

6. Remove air breather hose. Refer to TM-28, "Removal and Installation".

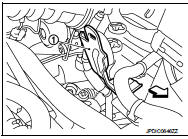

7. Remove bracket (1).

: Vehicle front

: Vehicle front

8. Disconnect selector cable and shifter cable from transaxle assembly. Refer to TM-25, "Removal and Installation".

9. Remove crankshaft position sensor. Refer to EM-228, "Disassembly and Assembly".

10. Remove clutch tube from CSC (Concentric Slave Cylinder) and then temporarily secure it to a position where it will not inhibit work. Refer to CL-25, "Removal and Installation".

CAUTION:

• Keep painted surface on the body or other parts free of clutch fluid. If it

spills, wipe up immediately

and wash the affected area with water.

• Never depress clutch pedal during removal procedure.

11. Remove fender protector LH. Refer to EXT-22, "Removal and Installation".

12. Disconnect ground cable.

13. Disconnect position switch connector. Refer to TM-24, "Removal and Installation".

14. Remove the harness clamp from rear housing.

15. Remove the engine harness clamp and then temporarily secure it to a position where it will not inhibit work.

16. Remove starter motor. Refer to STR-22, "HR16DE : Removal and Installation".

17. Remove front drive shafts. Refer to FAX-53, "Removal and Installation".

NOTE

:

Insert a suitable plug into differential side oil seal after removing front

drive shaft.

18. Set a suitable jack to transaxle assembly and then set a suitable jack to engine assembly.

CAUTION:

When setting a suitable jack, be careful so that it does not contact with the

switch.

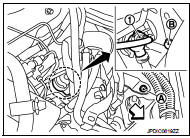

19. Remove engine mounting frame support (LH) (TBD) mounting bolts, as per the following procedure.

a. Remove bolt (A).

: Vehicle front

: Vehicle front

b. Release clutch damper (1) from bracket. Refer to CL-25, "Removal and Installation".

c. Remove bolt (B).

d. Remove engine mounting frame support (LH) mounting bolts from vehicle. Refer to EM-215, "Removal and Installation".

20. Remove rear engine mounting bracket and rear torque rod. Refer to EM-215, "Removal and Installation".

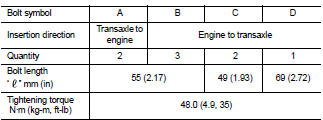

21. Remove transaxle assembly mounting bolts.

22. Remove transaxle assembly from the engine.

CAUTION:

• Fix transaxle assembly to a suitable jack.

• The transaxle assembly must not interfere with the wire harnesses and clutch tube.

23. Remove engine mounting bracket (LH) (TBD) and engine mounting frame support (LH) (TBD) from transaxle assembly. Refer to EM-215, "Removal and Installation".

24. Remove CSC. Refer to CL-27, "Removal and Installation".

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

• Fix transaxle assembly to a suitable jack.

• The transaxle assembly must not interfere with the wire harnesses and clutch tube.

• When installing transaxle assembly, never bring input shaft into contact with clutch cover.

• Tapping work for tapping bolts is not applied to new clutch housing. Do not perform tapping by other than screwing tapping bolts because tapping is formed by screwing tapping bolts into clutch housing.

• Tighten transaxle assembly mounting bolts to the specified torque.

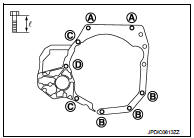

The figure is the view from the engine.

Inspection

INSPECTION AFTER INSTALLATION

• Check the operation of the control linkage. Refer to TM-27, "Inspection".

• Check the oil leakage and the oil level. Refer to TM-22, "Inspection".

5TH main gear assembly

5TH main gear assembly

Removal and Installation

REMOVAL

1. Shift the shifter lever to the 3rd gear position.

2. Disconnect the shifter cable and the selector cable from shifter lever A and

selector lever. Refer to TM-2 ...

Other materials:

Hazard function

Component Function Check

1.CHECK FUNCTION

1. Select “MULTI REMOTE ENT” of “BCM” using CONSULT-III.

2. Select “FLASHER” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >> Hazard warning lam ...

Filament

Inspection and Repair

INSPECTION

1. When measuring voltage, wrap tin foil around the top of the negative

probe. Then press the foil against the wire with your finger.

2. Attach probe circuit tester (in Volt range) to middle portion of

each filament.

3. If a filament is burned out, circuit ...

P1811 power supply circuit for 4wd control module

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With ...