Nissan Juke Service and Repair Manual : Stall test

Work Procedure

INSPECTION

1. Check the engine oil level. Replenish if necessary. Refer to LU-25, "Inspection".

2. Check for leak of the CVT fluid. Refer to TM-480, "Inspection".

3. Drive for about 10 minutes to warm up the vehicle so that the CVT fluid temperature is 50 to 80°C (122 to 176°F).

4. Be sure to apply the parking brake and block the tires.

5. Start the engine, depress the brake pedal and put the selector lever to the D position.

6. While depressing the brake pedal, depress the accelerator pedal gradually.

7. Read the stall speed quickly. Then, release your foot from the accelerator pedal quickly.

CAUTION:

Never depress the accelerator pedal for 5 seconds or more during the test.

Stall speed : Refer to TM-512, "Stall Speed".

8. Place the selector lever in the N position.

9. Cool the CVT fluid.

CAUTION:

Run the engine with the idle speed for at least 1 minute.

10. Put the selector lever to the R position and perform Step 6 to Step 9 again.

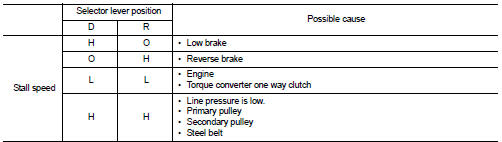

NARROWING-DOWN MALFUNCTIONING PARTS

O: Within the stall speed standard value H: Stall speed is higher than the standard value.

L: Stall speed is lower than the standard value.

CVT fluid

CVT fluid

Replacement

CVT fluid : Refer to TM-512, "General Specification".

Fluid capacity : Refer to TM-512, "General Specificatio

CAUTION:

• Use only Genuine NISSAN CVT Fluid NS-2. Using tr ...

Line pressure test

Line pressure test

Work Procedure

INSPECTION

1. Check the engine oil level. Replenish if necessary. LU-25, "Inspection".

2. Check for leak of the CVT fluid. Refer to TM-480, "Inspection".

3. Driv ...

Other materials:

B1058, B1059, B1060, B1061, B1062, B1063 diagnosis sensor unit

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

Diagnosis system (BCM) (with intelligent key system)

Common item

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the fo ...

P047B exhaust gas pressure sensor 2

DTC Logic

DTC DETECTION LOGIC

Diagnosis Proce

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF and wait at least 20 seconds.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO 2.

...