Nissan Juke Service and Repair Manual : P0720 output speed sensor

DTC Logic

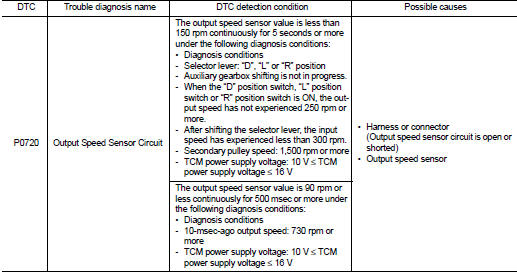

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

1. Start the engine.

2. Drive the vehicle.

3. Maintain the following conditions for 10 seconds or more.

Selector lever : “D” position Vehicle speed : 55 km/h (34 MPH) or more

4. Stop the vehicle.

5. Check the first trip DTC.

Is “P0720” detected? YES >> Go to TM-413, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

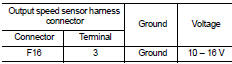

1.CHECK OUTPUT SPEED SENSOR POWER CIRCUIT

Check the voltage between the output speed sensor harness connector terminal and ground.

Is the check result normal? YES >> GO TO 6.

NO >> GO TO 2.

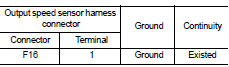

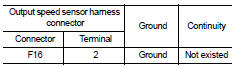

2.CHECK OUTPUT SPEED SENSOR GROUND CIRCUIT

Check the continuity between the output speed sensor harness connector terminal and ground.

Is the check result normal? YES >> GO TO 3.

NO >> Repair or replace the malfunctioning parts.

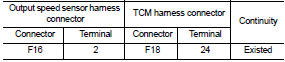

3.CHECK CIRCUIT BETWEEN OUTPUT SPEED SENSOR AND TCM (PART 1)

1. Turn ignition switch OFF.

2. Disconnect the TCM connector.

3. Check the continuity between the output speed sensor harness connector terminal and the TCM harness connector terminal.

Is the check result normal? YES >> GO TO 4.

NO >> Repair or replace the malfunctioning parts.

4.CHECK CIRCUIT BETWEEN OUTPUT SPEED SENSOR AND TCM (PART 1)

Check the continuity between the output speed sensor harness connector terminal and ground.

Is the check result normal? YES >> GO TO 5.

NO >> Repair or replace the malfunctioning parts.

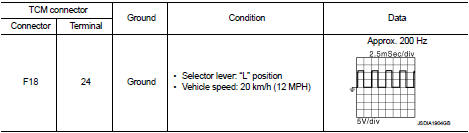

5.CHECK TCM INPUT SIGNALS

1. Connect all of the disconnected connectors.

2. Lift the vehicle.

3. Start the engine.

4. Check the frequency of the output speed sensor.

Is the check result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace the output speed sensor. Refer to TM-497, "Exploded View".

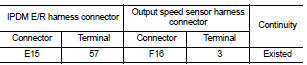

6.CHECK CIRCUIT BETWEEN IPDM E/R AND OUTPUT SPEED SENSOR (PART 1)

1. Disconnect the IPDM E/R connector.

2. Check the continuity between the IPDM E/R harness connector terminal and the output speed sensor harness connector terminal.

Is the check result normal? YES >> GO TO 7.

NO >> Repair or replace the malfunctioning parts.

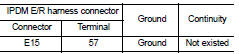

7.CHECK CIRCUIT BETWEEN IPDM E/R AND OUTPUT SPEED SENSOR (PART 2)

Check the continuity between the IPDM E/R vehicle-side harness connector terminal and ground.

Is the check result normal? YES >> GO TO 8.

NO >> Repair or replace the malfunctioning parts.

8.DETECTION OF MALFUNCTION ITEMS

Check the following items: • Harness open circuit or short circuit between the ignition switch and IPDM E/R. Refer to PG-15, "Wiring Diagram - IGNITION POWER SUPPLY -".

• 10A fuse (No.55, IPDM E/R). Refer to PG-25, "Fuse, Connector and Terminal Arrangement".

• IPDM E/R

Is the check result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace the malfunctioning parts.

P0715 input speed sensor A

P0715 input speed sensor A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just befor ...

P0740 torque converter

P0740 torque converter

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE OPERATION (PART 1)

If another "DTC CONFIRMATION PROCEDURE" occ ...

Other materials:

Removal and installation

COMBINATION METER

Exploded View

REMOVAL

Refer to IP-12, "Exploded View".

DISASSEMBLY

1. Front cover

2. Unified meter control unit

Removal and Installation

REMOVAL

1. Remove cluster lid A. Refer to IP-13, "Removal and Installation".

2. Remove the mounting screws of ...

Ignition coil, spark plug and rocker cover

Exploded View

1. Ignition coil

2. Spark plug

3. Rocker cover

4. Hose cramp

5. PCV hose

6. PCV valve

7. O-ring

8. Gasket

9. Oil filler cap

10. O-ring

11. Camshaft position sensor (INT)

12. Camshaft position sensor (EXH)

13. Cramp

A. To intake manifold

: Always replace after e ...

Sensor rotor

Front sensor rotor : Removal and Installation

REMOVAL

Replace wheel hub as an assembly when replacing because sensor rotor cannot

be disassembled. Refer to

FAX-43, "Removal and Installation".

INSTALLATION

Replace wheel hub as an assembly when replacing because sensor rotor cannot ...