Nissan Juke Service and Repair Manual : G sensor

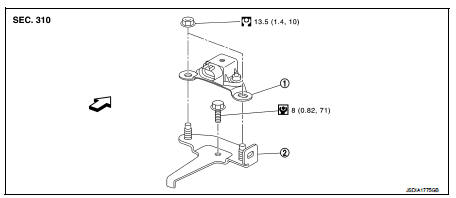

Exploded View

1. Bracket

2. G sensor

: Vehicle front

: Vehicle front

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

Removal and Installation

CAUTION:

• Never drop or strike G sensor, because it has little tolerance for impact.

• Never use a power tool to avoid impact.

REMOVAL

1. Disconnect the battery cable from the negative terminal. Refer to PG-124, "Removal and Installation".

2. Remove driver seat (LHD) or passenger seat (RHD). Refer to SE-19, "Removal and Installation".

3. Remove center pillar lower garnish (left side) and dash side finisher (left side). Refer to INT-20, "CENTER PILLAR LOWER GARNISH : Removal and Installation" (center pillar lower garnish) and INT-20, "DASH SIDE FINISHER : Removal and Installation" (dash side finisher).

4. Pull up floor carpet. Refer to INT-23, "Removal and Installation".

5. Disconnect G sensor harness connector.

6. Remove G sensor.

7. Remove bracket.

INSTALLATION

Installation is the reverse order of removal.

Adjustment

ADJUSTMENT AFTER INSTALLATION

Perform “G SENSOR CALIBRATION”. Refer to TM-377, "Description".

Air breather hose

Air breather hose

Removal and Installation

REMOVAL

1. Remove clip from bracket.

2. Remove air breather hose from transaxle assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

...

Oil pan

Oil pan

Exploded View

1. Transaxle assembly

2. Oil pan gasket

3. Magnet

4. Oil pan

5. Overflow tube

6. Drain plug gasket

7. Drain plug

8. Oil pan fitting bolt

: Always replace after every

di ...

Other materials:

Evaporative emission system

Inspection

1. Visually inspect EVAP vapor lines for improper attachment and for cracks,

damage, loose connections,

chafing and deterioration.

2. Check EVAP canister as follows:

a. Block port (A). Orally blow air through port (B).

Check that air flows freely through port (C).

b. Block port (B ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...

Component parts

Component Parts Location

1. Combination meter

2. Key switch

3. BCM

Refer to BCS-96, "BODY CONTROL

SYSTEM : Component Parts Location"

4. Power window main switch

(door lock/unlock switch)

5. Front door switch (driver side)

6. Front door lock assembly (driver

side)

7. Back do ...