Nissan Juke Service and Repair Manual : Diagnosis and repair workflow

Work Flow

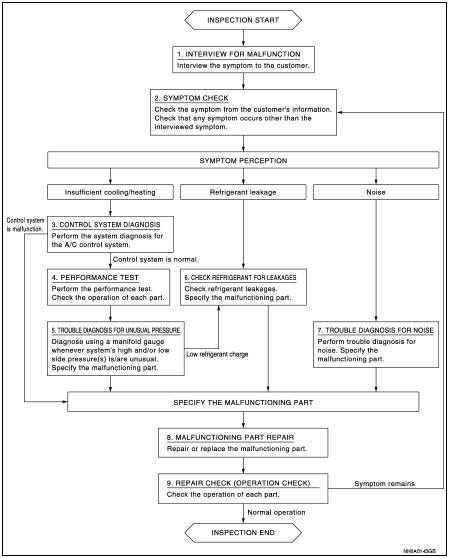

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Interview the symptom to the customer.

>> GO TO 2.

2.SYMPTOM CHECK

Check the symptom from the customer's information. Check that any symptom occurs other than the interviewed symptom.

Insufficient cooling/heating>>GO TO 3.

Refrigerant leakage>>GO TO 6.

Noise >> GO TO 7.

3.CONTROL SYSTEM DIAGNOSIS

Perform the system diagnosis for the A/C control system.

• Refer to HAC-44, "Work Flow". (AUTOMATIC AIR CONDITIONING: 4WD models) • Refer to HAC-135, "Work Flow". (AUTOMATIC AIR CONDITIONING: 2WD models) • Refer to HAC-216, "Work Flow". (MANUAL AIR CONDITIONING: 4WD models) • Refer to HAC-271, "Work Flow". (MANUAL AIR CONDITIONING: 2WD models)

Is A/C control system normal? YES >> GO TO 4.

NO >> GO TO 8.

4.PERFORMANCE TEST

Perform the performance test. Check the operation of each part. Refer to HA-81, "Inspection".

>> GO TO 5.

5.TROUBLE DIAGNOSIS FOR UNUSUAL PRESSURE

Diagnose using a manifold gauge whenever system's high and/or low side pressure(s) is/are unusual. Specify the malfunctioning part. Refer to HA-83, "Symptom Table".

Low refrigerant charge>>GO TO 6.

Except above>>GO TO 8.

6.CHECK REFRIGERANT FOR LEAKAGES

Check refrigerant for leakages. Specify the malfunctioning part. Refer to HA-74, "Leak Test".

>> GO TO 8.

7.TROUBLE DIAGNOSIS FOR NOISE

Perform trouble diagnosis for noise. Specify the malfunctioning part. Refer to HA-85, "Symptom Table".

>> GO TO 8.

8.MALFUNCTION PART REPAIR

Repair or replace the malfunctioning part.

>> GO TO 9.

9.REPAIR CHECK (OPERATION CHECK)

Check the operation of each part.

Does it operate normally? YES >> INSPECTION END

NO >> GO TO 2.

Basic inspection

Basic inspection

...

Refrigerant

Refrigerant

Description

CONNECTION OF SERVICE TOOLS AND EQUIPMENT

1. Shut-off valve

2. A/C service valve

3. Recovery/recycling/recharging

equipment

4. Vacuum pump

5. Manifold gauge set

6. Refrigeran ...

Other materials:

General Precautions

WARNING:

When replacing fuel line parts, be sure to observe the following.

• Put a “CAUTION: FLAMMABLE” sign in the workshop.

• Be sure to work in a well ventilated area and furnish workshop with a CO2 fire

extinguisher.

• Never smoke while servicing fuel system. Keep open flames and sparks ...

Condenser

Exploded View

Refer toINT-34, "Exploded View"

Removal and Installation

REMOVAL

1. Remove the back door lower finisher.

Refer to INT-35, "BACK DOOR LOWER FINISHER : Removal and Installation"

2. Remove bolt (A), and then remove condenser (1) from the vehicle

body.

INSTA ...

P0237, P0238 TC boost sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition swit ...