Nissan Juke Service and Repair Manual : Diagnosis and repair work flow

Work Flow

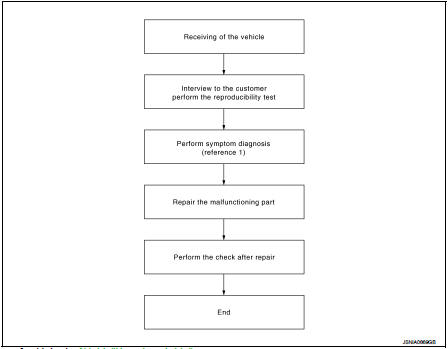

OVERALL SEQUENCE

Reference 1··· Refer to AV-77, "Symptom Table".

DETAILED FLOW

1.CHECK SYMPTOM

Check the malfunction symptoms by performing the following items.

• Interview the customer to obtain the malfunction information (conditions and environment when the malfunction occurred).

• Check the symptom.

>> GO TO 2.

2.PERFORM DIAGNOSIS BY SYMPTOM

Perform the relevant diagnosis referring to the diagnosis chart by symptom. Refer to AV-77, "Symptom Table".

>> GO TO 3.

3.REPAIR OR REPLACE MALFUNCTIONING PARTS

Repair or replace the malfunctioning parts.

>> GO TO 4.

4.FINAL CHECK

Perform the operation to check that the malfunction symptom is solved or any other symptoms are present.

Is there any symptom? YES >> GO TO 2.

NO >> INSPECTION END

Basic inspection

Basic inspection

...

Additional service when removing battery negative terminal

Additional service when removing battery negative terminal

Description

• The NAVI control unit is equipped with the anti-theft system.

• The NAVI control unit operates after authenticating a fixed four-digit

anti-theft code.

• After removing the battery ...

Other materials:

P0605 ECM

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn

ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE ...

C1601 battery power supply

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With ...

Locking with power door lock switch

Driver’s armrest

Operating the power door lock switch will lock or unlock all the doors. The switch

is located on the driver’s door armrest.

To lock the doors, push the power door lock switch to the lock position 1 with

the driver’s door open, then close the door.

When locking the door this ...