Nissan Juke Service and Repair Manual : Brake pedal

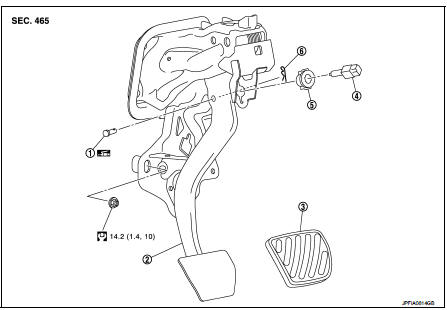

Exploded View

WITHOUT ESP

1. Clevis pin

2. Brake pedal assembly

3. Brake pedal pad

4. Stop lamp switch

5. Clip

6. Snap pin

: Apply multi-purpose grease.

: Apply multi-purpose grease.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

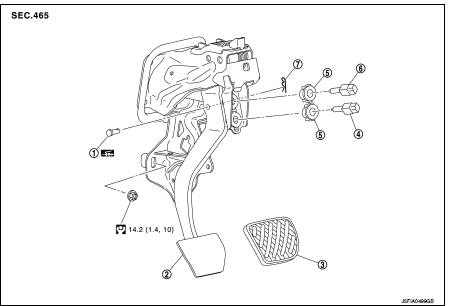

WITH ESP

1. Clevis pin

2. Brake pedal assembly

3. Brake pedal pad

4. Brake switch/brake pedal position

switch

5. Clip

6. Stop lamp switch

7. Snap pin

: Apply multi-purpose grease.

: N·m (kg-m, ft-l

Removal and Installation

REMOVAL

1. Remove instrument lower panel. Refer to IP-13, "Removal and Installation".

2. Disconnect the stop lamp switch and the brake switch/brake pedal position switch harness connectors.

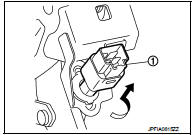

3. Rotate the stop lamp switch and the brake switch/brake pedal position switch (1) counter clockwise to remove.

4. Disconnect the accelerator pedal harness connector and harness clip.

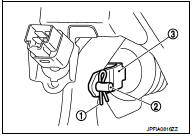

5. Remove snap pin (1) and clevis pin (2) from clevis (3) of brake booster.

6. Remove the brake pedal assembly.

CAUTION:

Hold the brake booster and master cylinder assembly so as

not to drop out or contact them other parts.

7. Remove accelerator pedal from brake pedal assembly. Refer to ACC-3, "Removal and Installation".

8. Perform inspection after removal. Refer to BR-90, "Inspection and Adjustment".

INSTALLATION

Note the following, and install in the reverse order of removal.

• Apply the multi-purpose grease to the clevis pin and the mating faces. (Not necessary if grease has been already applied) NOTE

:

The clevis pin may be inserted in either direction.

• Perform adjustment after installation. Refer to BR-90, "Inspection and Adjustment".

Inspection and Adjustment

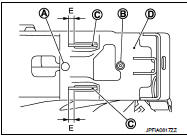

INSPECTION AFTER REMOVAL

• Check for the following items and replace the brake pedal assembly if necessary.

- Check the brake pedal upper rivet (made by aluminum) (A) and pin (B) for deformation.

- Check the brake pedal for bend, damage, and cracks on the welded parts.

- Check the lapping length (E) of sub-bracket (C) and slide plate (D).

E : 5.5 mm (0.217 in) or more

• Check clevis pin and plastic stopper (A) for damage and deformation.

If any is found, replace clevis pin.

ADJUSTMENT AFTER INSTALLATION

• Adjust each item of brake pedal after installing the brake pedal assembly to the vehicle. Refer to BR-77, "Inspection and Adjustment".

• Perform the release position learning of the accelerator pedal.

- HR16DE: Refer to EC-542, "Work Procedure".

- MR16DDT: Refer to EC-134, "Work Procedure".

Brake piping

Brake piping

Front : Exploded View

WITHOUT ESP

1. Brake booster

2. Master cylinder assembly

3. Brake tube

4. Connector bracket

5. Connector

6. ABS actuator and electric unit (control

unit)

7. Lock p ...

Other materials:

A/C unit assembly

Exploded View (Automatic Air Conditioning)

REMOVAL

LHD models (4WD)

1. A/C unit assembly

2. Drain hose

3. Steering member

4. Instrument stay

: Clip

: N·m (kg-m, ft-lb)

DISASSEMBLY

LHD models (4WD)

1. Ventilator seal

2. Defroster seal

3. Upper attachment case

4. Sub defroster do ...

Transaxle assembly

Exploded View

CASE AND HOUSING

1. Differential side oil seal

2. Clutch housing

3. 2 way connector

4. Oil gutter

5. Air breather inner tube

6. Filler plug

7. Gasket

8. Transaxle case

9. O-ring

10. Rear housing

11. Position switch

12. Dowel pin

13. Magnet

14. Drain plug

15. ...

Wiring diagram

SECURITY CONTROL SYSTEM

LHD

LHD : Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

RHD

RHD : Wiring D ...