Nissan Juke Service and Repair Manual : B1178 lap Pre-tensioner RH

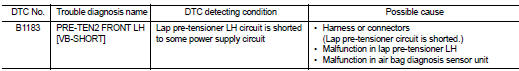

DTC Logic

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp status. Refer to SRC-12, "On Board Diagnosis Function".

NOTE

:

SRS does not enter diagnosis mode if no malfunction is detected in user mode.

Is malfunctioning part detected? YES >> Refer to SRC-131, "Diagnosis Procedure".

NO >> INSPECTION EN

Diagnosis Procedure

WARNING:

• Before servicing, turn ignition switch OFF, disconnect battery negative

terminal and wait at least 3

minutes. (To discharge backup capacitor.)

• Never use unspecified tester or other measuring device.

1.CHECK HARNESS CONNECTOR

Check the harness connector.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace harness connector.

2.CHECK WIRING HARNESS

Check the wiring harness externals.

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace wiring harness.

3.REPLACE LAP PRE-TENSIONER LH

1. Replace lap pre-tensioner LH. Refer to SR-33, "Removal and Installation".

2. Perform DTC confirmation procedure. Refer to SRC-131, "DTC Logic".

Is DTC detected? YES >> GO TO 4.

NO >> INSPECTION END

4.REPLACE AIR BAG DIAGNOSIS SENSOR UNIT

1. Replace air bag diagnosis sensor unit. Refer to SR-30, "Removal and Installation".

2. Perform DTC confirmation procedure. Refer to SRC-131, "DTC Logic".

Is DTC detected? YES >> GO TO 1.

NO >> INSPECTION END

Diagnosis Procedure

Diagnosis Procedure

WARNING:

• Before servicing, turn ignition switch OFF, disconnect battery negative

terminal and wait at least 3

minutes. (To discharge backup capacitor.)

• Never use unspecified tester or other m ...

B1179 lap Pre-tensioner RH

B1179 lap Pre-tensioner RH

DTC Logic

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

With ...

Other materials:

Compressor

Exploded View

REMOVAL

1. High-pressure flexible hose

2. O-ring

3. Compressor

4. O-ring

5. Low-pressure flexible hose

A. To condenser

B. To evaporator

: N·m (kg-m, ft-lb)

DISASSEMBLY

1. Compressor unit

2. Field coil

3. Snap ring

4. Pulley assembly

5. Snap ring

6. Shim

7. ...

Cleaning

If your windshield is not clear after using the windshield washer or if a wiper

blade chatters when running, wax or other material may be on the blade or windshield.

Clean the outside of the windshield with a washer solution or a mild detergent.

Your windshield is clean if beads do not form whe ...

Basic inspection

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related

malfunction, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

- Harness connectors for improper connections

- Wiring harness for improper connections, pinche ...