Nissan Juke Service and Repair Manual : Thermo plunger unit

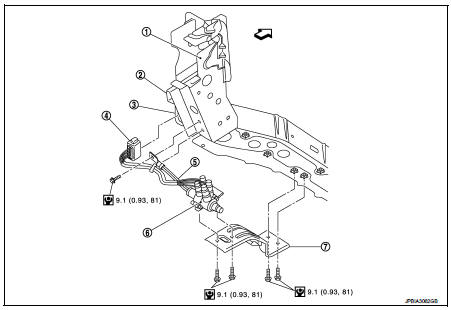

Exploded View

1. Side member LH

2. Thermo plunger control unit

3. Thermo plunger relay

4. Thermo plunger connector

5. Earth lead

6. Thermo plunger unit

7. Bracket stay

Vehicle front

Vehicle front

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

Removal and Installation

REMOVAL

1. Remove battery cable from the negative terminal.

2. Drain engine coolant. Refer to CO-62, "Draining".

3. Remove the fender protector (LH). Refer to EXT-22, "Exploded View".

4. Disconnect thermo plunger connector.

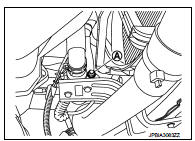

5. Remove the earth lead nut (A

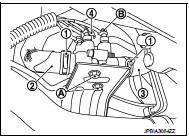

6. Remove the thermo plunger connection caps (4).

7. Remove the thermo plunger connection nuts (B) using the appropriate tool.

8. Remove the LH and RH clamps (1) and hoses (2) and (3).

9. Remove the fixing bolts (A) of the thermo plunger from the bracket and remove the thermo plunger unit.

Tightening torque of bolt : 9.1 N.m

INSTALLATION

Installation is basically the reverse order of the removal.

Water pump

Water pump

Exploded View

1. Water pump

2. Gasket

3. Cylinder block

Removal and Installation

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could occur

from high pressure ...

Thermostat

Thermostat

Inspection

• Place a thread so that it is caught in the valves of the thermostat.

Immerse fully in a container filled with water. Heat while stirring.

(The example in the figure shows the therm ...

Other materials:

Ignition coil, spark plug and rocker cover

Exploded View

1. Ignition coil

2. Spark plug

3. Rocker cover

4. Hose cramp

5. PCV hose

6. PCV valve

7. O-ring

8. Gasket

9. Oil filler cap

10. O-ring

11. Camshaft position sensor (INT)

12. Camshaft position sensor (EXH)

13. Cramp

A. To intake manifold

: Always replace after e ...

EPS warning lamp does not turn on

Description

EPS warning lamp does not turn ON when turning ignition switch ON from OFF.

(Check the illumination of the

EPS warning lamp.)

Diagnosis Procedure

1.CHECK EPS WARNING LAMP

Perform the trouble diagnosis of EPS warning lamp. Refer to STC-26,

"Diagnosis Procedure".

Is t ...

Basic inspection

Inspection and adjustment

Additional service when replacing control unit (BCM)

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT (BCM) : Description

BEFORE REPLACEMENT

When replacing BCM, save or print current vehicle specification with

CONSULT-III configuration before

replacement.

NOTE:

If ...