Nissan Juke Service and Repair Manual : P0197, P0198 EOT sensor

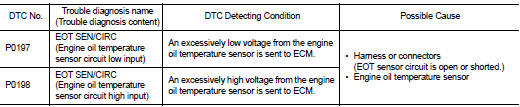

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and wait at least 5 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-251, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

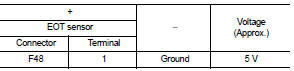

1.CHECK ENGINE OIL TEMPERATURE SENSOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect engine oil temperature (EOT) sensor harness connector.

3. Turn ignition switch ON.

4. Check the voltage between EOT sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

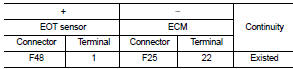

2.CHECK ENGINE OIL TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EOT sensor harness connector and ECM harness connector.

4. Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

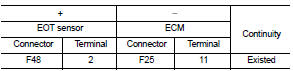

3.CHECK EOT SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EOT sensor harness connector and ECM harness connector.

4. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK ENGINE OIL TEMPERATURE SENSOR

Check the engine oil temperature sensor. Refer to EC-252, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace engine oil temperature sensor. Refer to EM-103, "Exploded View".

Component Inspection

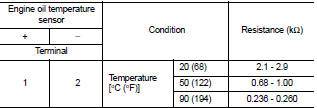

1.CHECK ENGINE OIL TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect engine oil temperature sensor harness connector.

3. Remove engine oil temperature sensor.

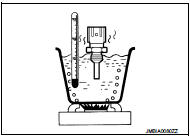

4. Check resistance between engine oil temperature sensor terminals by heating with hot water as shown in the figure.

Is the inspection result normal? YES >> INSPECTION END NO >> Replace engine oil temperature sensor. Refer to EM-103, "Exploded View".

P0190 FRP sensor

P0190 FRP sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

P0201, P0202, P0203, P0204 fuel injector

P0201, P0202, P0203, P0204 fuel injector

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

Other materials:

Refrigerant pressure sensor

Component Function Check

1.CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower fan switch ON.

3. Check the voltage between ECM harness connector and ground.]

Is the inspection result normal?

YES > ...

Transfer case

Exploded View

1. Pinion lock nut

2. Companion flange

3. Drive pion oil seal

4. Pinon rear bearing

5. Transfer case

6. Gasket

7. Filler plug

8. Collapsible spacer

9. Drive pinion adjust shim

10. Drive pinion

11. Pinion front bearing

12. Ring gear

13. Ring gear shaft

14. Ring ...

Power supply and ground circuit

Diagnosis Procedure

1.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) IGNITION POWER

SUPPLY

1. Turn the ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) harness connector.

3. Check voltage between ABS actuator and electric unit (control unit) harness

conne ...