Nissan Juke Service and Repair Manual : P0190 FRP sensor

DTC Logic

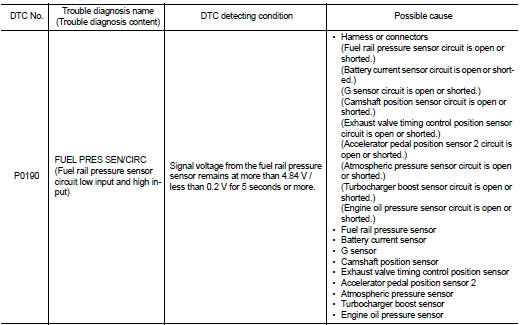

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is 11 V

or more at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start the engine ON and wait at least 60 seconds.

2. Check DTC or 1st trip DTC.

Is DTC or 1st trip DTC detected? YES >> Proceed to EC-247, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

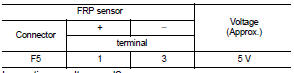

1.CHECK FUEL RAIL PRESSURE (FRP) SENSOR POWER SUPPLY-I

1. Turn ignition switch OFF.

2. Disconnect FRP sensor connector.

3. Turn ignition switch ON.

4. Check the voltage between FRP sensor harness connector terminals.

Inspection result normal? YES >> GO TO 6.

NO >> GO TO 2.

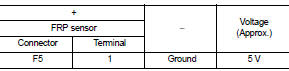

2.CHECK FRP SENSOR POWER SUPPLY-II

Check the voltage between FRP sensor harness connector and the ground.

Is inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

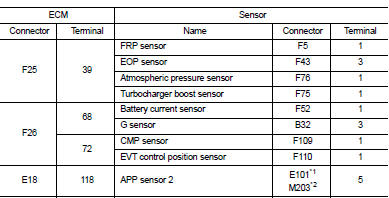

3.CHECK SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness connector for short to power and short to ground, between the following terminals.

*1: LHD models or RHD with CVT models *2: RHD with M/T models

Is inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

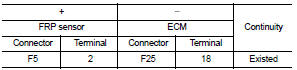

4.CHECK FRP SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between FRP sensor harness connector and ECM harness connector.

4. Also check harness for short to power.

Is inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

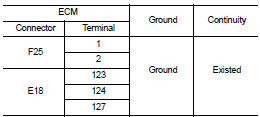

5.CHECK ECM GROUND CIRCUIT

Check the continuity between ECM harness connector and the ground.

Is inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace error-detected parts.

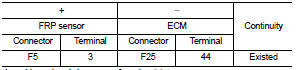

6.CHECK FRP SENSOR SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between FRP sensor harness connector and ECM harness connector.

4. Also check harness for short to ground and to power.

Is inspection result normal? YES >> GO TO 7.

NO >> Repair or replace error-detected parts.

7.CHECK FRP SENSOR

Check the FRP sensor. Refer to EC-249, "Component Inspection".

Is inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace error-detected parts.

Component Inspection

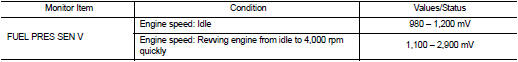

1.CHECK FRP SENSOR

WITH CONSULT-III

WITH CONSULT-III

1. Turn ignition switch OFF.

2. Reconnect harness connector disconnected.

3. Start the engine.

4. Select “DATA MONITOR” mode of “ENGINE” using CONSULT-III.

5. Check that the “FUEL PRES SEN V” indication.

WITHOUT CONSULT-III

WITHOUT CONSULT-III

1. Turn ignition switch OFF.

2. Reconnect harness connector disconnected.

3. Start the engine.

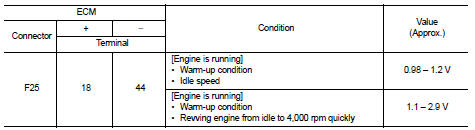

4. Check FRP sensor signal voltage.

Is the inspection result normal? YES >> INSPECTION END.

NO >> Replace FRP sensor. Refer to EM-47, "Exploded View".

P0172 fuel injection system function

P0172 fuel injection system function

DTC Logic

DTC DETECTION LOGIC

With the Air/Fuel Mixture Ratio Self-Learning Control, the actual mixture

ratio can be brought closely to the

theoretical mixture ratio based on the mixture ratio fe ...

P0197, P0198 EOT sensor

P0197, P0198 EOT sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

Other materials:

P181E steering angle sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With ...

Precaution

Precautions for Suspension

• When installing rubber bushings, the final tightening must be carried out

under unladen conditions with tires

on ground. Spilled oil might shorten the life of rubber bushings. Be sure to

wipe off any spilled oil.

- Unladen conditions mean that fuel, engine coolant ...

General Specification

CAUTION:

• Use only Genuine NISSAN CVT Fluid NS-2. Never mix with other fluid.

• Using CVT fluid other than Genuine NISSAN CVT Fluid NS-2 will deteriorate in

driveability and CVT durability, and may damage

the CVT, which is not covered by the warranty.

*1: Refer to MA-13, "Fluids and Lu ...