Nissan Juke Service and Repair Manual : Front wiper auto stop signal circuit

Component Function Check

1.CHECK FRONT WIPER (AUTO STOP) SIGNAL

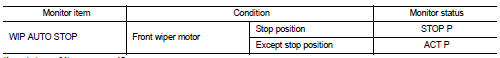

CONSULT-III DATA MONITOR

CONSULT-III DATA MONITOR

1. Select “WIP AUTO STOP” of IPDM E/R data monitor item.

2. Operate the front wiper.

3. With the front wiper operation, check the monitor status.

Is the status of item normal? YES >> Auto stop signal circuit is normal.

NO >> Refer to WW-40, "Diagnosis Procedure".

Diagnosis Procedure

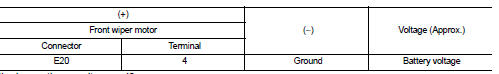

1.CHECK IPDM E/R OUTPUT VOLTAGE

1. Turn ignition switch OFF.

2. Disconnect front wiper motor connector.

3. Turn ignition switch ON.

4. Check voltage between front wiper motor harness connector and ground.

Is the inspection result normal? YES >> Replace front wiper motor.

NO >> GO TO 2.

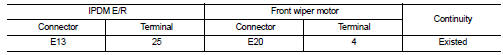

2.CHECK FRONT WIPER MOTOR (AUTO STOP) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

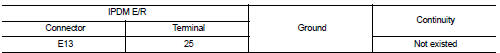

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

4. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> Replace IPDM E/R.

NO >> Repair or replace harness.

Front wiper motor hi circuit

Front wiper motor hi circuit

Component Function Check

1.CHECK FRONT WIPER HI OPERATION

CONSULT-III ACTIVE TEST

1. Select “FRONT WIPER” of IPDM E/R active test item.

2. With operating the test item, check front wiper operation ...

Front wiper motor ground circuit

Front wiper motor ground circuit

Diagnosis Procedure

1.CHECK FRONT WIPER MOTOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front wiper motor connector.

3. Check continuity between front wiper motor harness connector ...

Other materials:

Exploded View

1. Mounting rubber

2. Main muffler

3. Seal bearing

4. Spring

5. Mounting rubber

6. Seal bearing

7. Exhaust front tube

8. Heated oxygen sensor 2

9. Sub muffler

10. Gasket

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

...

Exhaust valve timing control

Exhaust valve timing control : System Diagram

Exhaust valve timing control: System Description

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

This mechanism hydraulically controls cam phases continuously with the fixed

operating angle of the exhaust

valve.

The ECM receives signals such ...

P1553 battery current sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following before conducting

the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. ...