Nissan Juke Service and Repair Manual : Electrical load signal

Description

The electrical load signal (Headlamp switch signal, rear window defogger switch signal, etc.) is transferred via the CAN communication line.

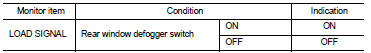

Component Function Check

1.CHECK REAR WINDOW DEFOGGER SWITCH FUNCTION

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode of “ENGINE” using CONSULT-III.

3. Select “LOAD SIGNAL” and check indication as per the following conditions.

Is the inspection result normal? YES >> GO TO 2.

NO >> Proceed to EC-418, "Diagnosis Procedure".

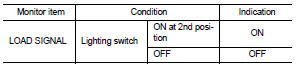

2.CHECK LIGHTING SWITCH FUNCTION

With CONSULT-III

With CONSULT-III

Check “LOAD SIGNAL” indication as per the following conditions.

Is the inspection result normal? YES >> GO TO 3.

NO >> Proceed to EC-418, "Diagnosis Procedure".

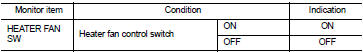

3.CHECK HEATER FAN CONTROL SWITCH FUNCTION

With CONSULT-III

With CONSULT-III

Select “HEATER FAN SW” and check indication as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-418, "Diagnosis Procedure".

Diagnosis Procedure

1.INSPECTION START

Confirm the malfunctioning circuit (rear window defogger, headlamp or heater fan). Refer to EC-418, "Component Function Check".

Which circuit is related to the incident? Rear window defogger>>GO TO 2.

Headlamp>>GO TO 3.

Heater fan>>GO TO 4.

2.CHECK REAR WINDOW DEFOGGER SYSTEM

Check the rear window defogger system. Refer to DEF-25, "Work Flow".

>> INSPECTION END 3.CHECK HEADLAMP SYSTEM

Check the headlamp system. Refer to EXL-43, "Work Flow".

>> INSPECTION END 4.CHECK HEATER FAN CONTROL SYSTEM

Check the heater fan control system. refer to HA-72, "Work Flow".

>> INSPECTION END

Ignition signal

Ignition signal

Component Function Check

1.INSPECTION START

Turn ignition switch OFF, and restart engine.

Does the engine start?

YES >> GO TO 2.

NO >> Proceed to EC-414, "Diagnosis Procedure ...

Cooling fan

Cooling fan

Component Function Check

1.CHECK COOLING FAN FUNCTION

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “FAN DUTY CONTROL” in “ACTIVE TEST” mode of “ENGINE” using

CONSULT-III.

3. Check th ...

Other materials:

P0110 IAT sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or ...

P0172 fuel injection system function

DTC Logic

DTC DETECTION LOGIC

With the Air/Fuel Mixture Ratio Self-Learning Control, the actual mixture

ratio can be brought closely to the

theoretical mixture ratio based on the mixture ratio feedback signal from the

A/F sensor 1. The ECM calculates

the necessary compensation to correct the ...

Avoiding collision and rollover

WARNING

Failure to operate this vehicle in a safe and prudent manner may result in

loss of control or an accident.

Be alert and drive defensively at all times. Obey all traffic regulations. Avoid

excessive speed, high speed cornering, or sudden steering maneuvers, because these

driving pract ...