Nissan Juke Service and Repair Manual : ECM branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the ECM for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of ECM.

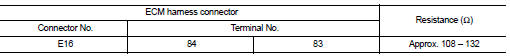

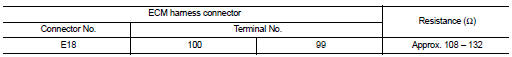

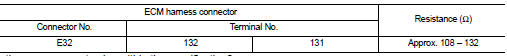

2. Check the resistance between the ECM harness connector terminals.

- HR16DE models

- MR16DDT models

- K9K models

Is the measurement value within the specification? YES >> GO TO 3.

NO >> Repair the ECM branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the ECM. Refer to the following.

• HR16DE: EC-566, "Diagnosis Procedure" • MR16DDT: EC-155, "Diagnosis Procedure" • K9K: EC-885, "Diagnosis Procedure"

Is the inspection result normal? YES (Present error)>>Replace the ECM. Refer to the following.

• HR16DE: EC-805, "Removal and Installation" • MR16DDT: EC-447, "Removal and Installation" • K9K: EC-879, "Work Procedure"

YES (Past error)>>Error was detected in the ECM branch line.

NO >> Repair the power supply and the ground circuit.

Main line betweeN DLC and MDU circuit

Main line betweeN DLC and MDU circuit

Diagnosis Procedure

1.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect the following harness conne ...

4WD branch line circuit

4WD branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend ...

Other materials:

How to select piston and bearing

Description

• The identification grade stamped on each part is the grade for the

dimension measured in new condition. This grade cannot apply to reused parts.

• For reused or repaired parts, measure the dimension accurately. Determine the

grade by comparing the

measurement with the values o ...

Oil pan (upper)

Exploded View

1. O-ring

2. Oil pan (upper)

3. Oil level gauge guide

4. O-ring

5. Oil level gauge

6. Oil pump drive chain

7. Crankshaft sprocket

8. Oil pump sprocket

9. Oil pump chain tensioner

10. Oil pump

11. Drain plug

12. Drain plug washer

13. Oil pan (lower)

14. Oil filt ...

Illumination

Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation: if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

...