Nissan Juke Service and Repair Manual : Removal and Installation

REMOVAL

1. Remove engine assembly. Refer to EM-55, "2WD : Exploded View" (2WD) , EM-59, "4WD : Exploded View" (4WD).

2. Remove oil pan (lower). Refer to EM-41, "Removal and Installation".

3. Remove front cover, and other related parts. Refer to EM-67, "Exploded View".

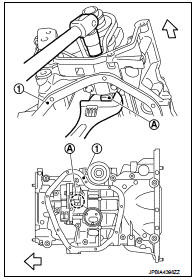

4. Remove oil pump sprocket with the following procedure: • Add matching mark if necessary for easier installation.

a. Push oil pump drive chain tensioner (1) in the direction show in the figure (A).

b. Insert a stopper pin (A) into the body hole (B).

c. Remove oil pump chain tensioner.

• When the holes on lever and tensioner body cannot be aligned, align these holes by slightly moving the oil pump chain tensioner slack guide.

![d. Hold the WAF part of oil pump shaft [WAF: 10 mm (0.39 in)] (A),](images/books/335/8/index.46.jpg)

d. Hold the WAF part of oil pump shaft [WAF: 10 mm (0.39 in)] (A), and then loosen the oil pump sprocket bolt and remove it.

1 : Oil pan (upper)

: Engine front

: Engine front

CAUTION:

• Secure the oil pump shaft with the WAF part.

• Never loosen the oil pump sprocket bolt by tightening the oil pump drive chain.

e. Remove oil pump sprocket.

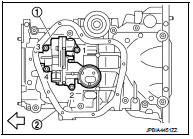

5. Remove oil pump.

• Loosen bolts in reverse order as shown in the figure.

1 : Oil pump

2 : Oil pan (upper)

: Engine front

: Engine front

INSTALLATION

Note the following, and install in the reverse order of removal.

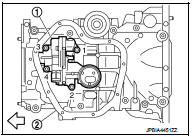

Oil Pump

• Tighten bolts in numerical order as shown in the figure.

1 : Oil pump

2 : Oil pan (upper)

: Engine front

: Engine front

Exploded View

Exploded View

1. O-ring

2. Oil pan (upper)

3. Oil level gauge guide

4. O-ring

5. Oil level gauge

6. Oil pump drive chain

7. Crankshaft sprocket

8. Oil pump sprocket

9. Oil pump chain tensioner

10. ...

Inspection

Inspection

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to LU-8, "Inspection".

2. Start the engine, and check that there is no leakage of engine oil.

3. Stop the engine and wai ...

Other materials:

Precaution for Brake System

WARNING:

Clean any dust from the front brake and rear brake using a vacuum dust

collector. Never blow by compressed

air.

• Brake fluid use refer to MA-13, "Fluids and Lubricants".

• Never reuse drained brake fluid.

• Never spill or splash brake fluid on painted surfaces. Brake fluid ...

Main line betweeN DLC and MDU circuit

Diagnosis Procedure

1.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect the following harness connectors.

- ECM

- Multi display unit

4. Check the continuity between the data link connector and the ...

Fuel level sensor unit, fuel filter and fuel pump assembly

Exploded View

1. Fuel tank

2. Rock ring

3.

Fuel level sensor unit, fuel filter and

fuel pump assembly

4. O-ring

: Vehicle front

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

1. Fuel filter and fuel pump assembly

2. Fuel gauge

Removal and Installation

WARNING:

...